Over the last two decades, we have seen significant growth within 3D printing technologies. There have been various types of processes, including:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SLA, FDM, and SLS are some of the most widely used and established processes.

FDM technologies are currently the most popular platforms regarding usage and affordability. These platforms are often seen on social media, with desktop footprints creating various crafty items. Included in this category are the 3D extruder handheld pens. There are a variety of colored, multicolored, and specialty blends of thermoplastic filaments used in these extrusion-type machines. This allows for various color combinations and customizations for the end project. FDM is one of the most widespread options for an entry-level craft or rapid prototype, delivering a diverse range of uses.

SLA and other resin 3D printing platforms have also become quite popular over the years. This photopolymerization process is achieved by using a laser to cure liquid resin. Parts created with this process offer the highest accuracy and resolution and the smoothest finish. While both FDM and SLA are a part of the additive manufacturing family, both require post-process finishing and painting.

With more industrial processes like SLS, support structures needed in FDM and SLA are not required. Sintering processes can use multiple material types to produce 3D objects. A laser is used to bond small particles of powdered material. This process is a popular choice within the manufacturing and engineering sectors.

Full-color 3D printing

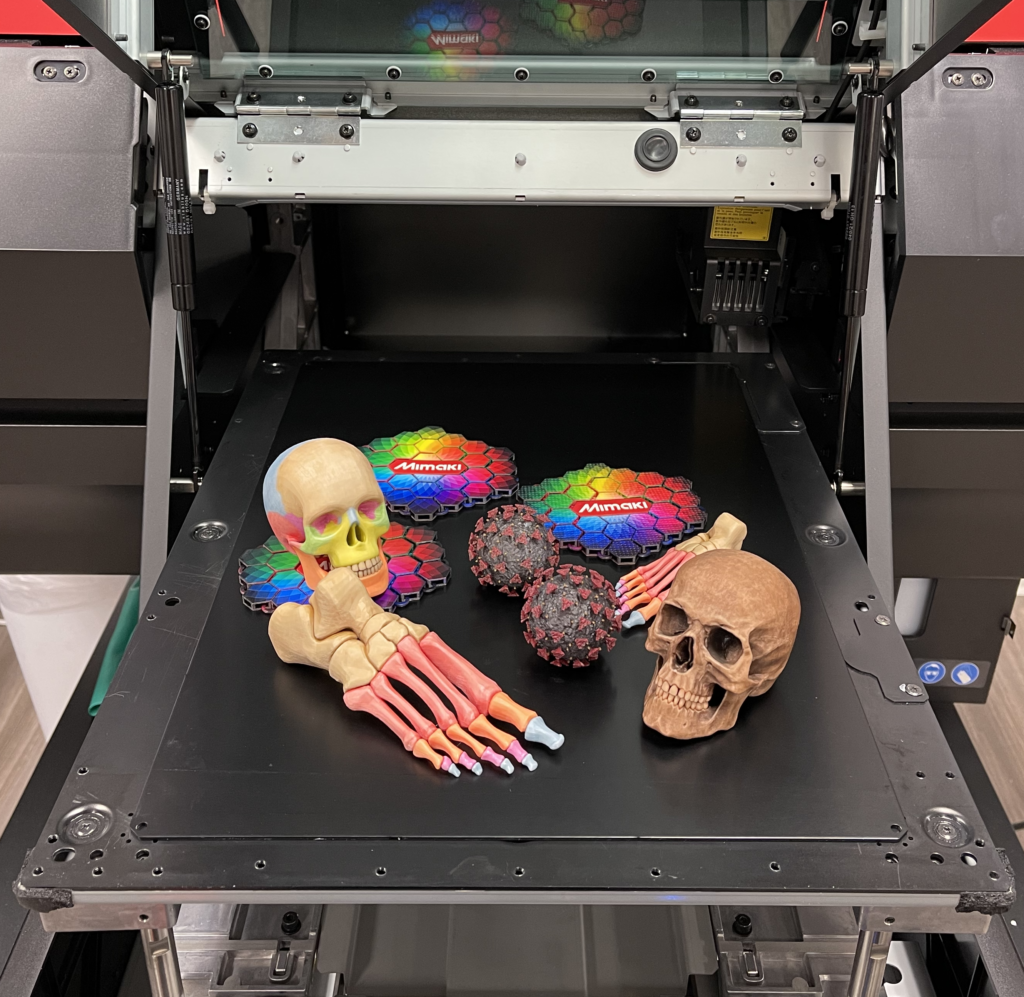

Still, the above-mentioned technologies cannot capture full-color 3D printing. There are a handful of full-color 3D printing platforms available on the market. Some of the most popular are from Mimaki, 3D Systems, Stratasys, and HP. While there is an increasing amount of small desktop options, like the XYZ printing da Vinci Color, for performance and versatility, the four mentioned above stand out.

3D Systems has the ProJet series, which starts at around the mid-$30,000s. These systems use a powdered polymer core with a binder and inkjet heads. The ProJet line has many features but does require post-processing and limited options for materials. HP has the Jet Fusion line that starts in the mid-$50,000s. This system also uses powdered polymers with an infrared curing light and inkjet. The Jet Fusion line does require a cooling time and post-processing.

Stratasys’ PolyJet Series, like the J55, is priced around $100,000. Stratasys has several decades of experience in 3D print technology, which is highlighted in this UV light-cured resin series. The PolyJet series comes at a higher price point and requires support structures. Mimaki has its 3D series of equipment with the 3DUJ-553 & 3DUJ-2207, which has the 2207 starting at around $40,000. These platforms utilize a UV-curable resin which is supported by a water-soluble solution. With the widest color spectrum, these platforms require support and print with one material.

Why should a shop adopt 3D printing technology?

- It offers versatility in color and the ability to create photorealistic models.

- With the now mainstreamed adoption of 3D printing, it’s time to see how 3D can help your target markets and customers, with offerings outside of wide-format printing and finishing.

- For a long time, price-point restrictions were an obstacle that separated commercial and industrial applications.

- From gaming community projects to giant figurines, like Funko POP, to exhibitions needing 3D displays, this printing platform can bring sales power to your print shop at an attractive price point. Many graphics printers are utilizing 3D solutions in their current workflows and offerings.

- Partnering with artists to create 3D artwork is another channel of possibilities. Dennis Harroun is a great example of how multiple processes can bring creativity to life.

Advantages

One of the key advantages is the diverse range of applications. Collectibles, figurines, and scaled models are all possible with 3D printing. With the high-resolution print heads, you can achieve 1,200 PPI for more demanding applications such as prototyping and educational applications. This is partly due to the photorealistic color gamut, including clear, of up to 10 million color combinations.

Challenges

- 3D modeling and other parametric designs require more time than a standard 2-dimensional print.

- Not all models are compatible with all processes.

- Some simple designs might require a specific orientation when being produced.

- The way a model is arranged on the build plate will ultimately have an impact on the final finished surface, which is something most users wouldn’t think about

- Other designs might require support structures to be added.

- One of the other learning curves was to realize that some renderings made for a nice image but were not ready as is to be produced in 3D.

Outside of modeling and software learning, there is an aspect of time management that is required as well:

- Run-time on some of these models is significant, so proper planning on timeframes is required.

- Use the time estimator and consumables calculators within the software for proper planning. For example, Mimaki 3D Link will estimate ink/support consumption before print execution and warns users if ink or waste tank levels are less than acceptable.

- Cycle times aren’t detrimental as you don’t have to watch the machine, and you are free to go about other projects during the run.

- Onboard camera feeds help with peace of mind while running complex projects over the weekend or at night.

- There are also considerations on additional post-process options after the support solution is removed to get the desired look and feel on a model, such as a more polished look on transparent objects.

3D printed projects

As with any new project, it starts with a lot of measuring. First, start with a base model. Then, start customizing textures, colors, and scale. Once you have those squared away, upload your work into a file checker to repair and optimize any conflicts. After that process, load the files into the operating software to output to the machine.