A Word on the Future of Screen Printing Technology

While screen printing is one of the oldest printing processes, it remains a popular method today due to its ability to print on a broad range of substrates. While some screen printing techniques only work on a limited number of substrates, screen printing is appropriate for countless projects. For T-shirt designers, it offers a wide selection of ink colors and produces great ink-film thickness.

While some practitioners of other printing techniques believe screen printing will disappear or become much less common in the future, it is likely to continue to thrive as a vital production process.

So, what does the future of screen printing look like? Let’s take a closer look at how some evoltions in screen printing could impact T-shirt printers.

Areas to Evolve

Screen printing may be the printing technique of choice for many T-shirt designers, but it is not without its flaws. As customer demand for speed continues to grow, many screen printers are struggling to keep up. For the process to remain a viable, thriving solution for printing bulk T-shirts in the future, it needs to be modernized to make it faster, more repeatable, and more cost-effective.

Slow production speed is a problem for screen printers, and production must be increased to compete with other technologies that allow for faster production. Improved technology is driving many changes in the world of screen printing.

Roller Squeegees

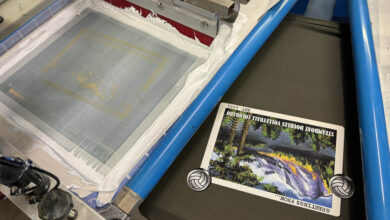

While a majority of print processes use roller-based in-transfer systems to improve speed and efficiency, screen printing does not. Instead, squeegee blades are used to transfer ink through the screen and onto the shirt or another substrate.

In the future, roller squeegees are likely to replace squeegee blades. This upgrade would allow for higher speed and productivity while maintaining consistent ink-film thickness. While ideal, particularly for cylinder and web press formats, roller squeegees may also prove useful for flatbed screen printing presses.

Easier Pre-Press

The pre-press phase is one area where modern technology is helping screen printers save time. Computer-to-screen systems take some of the work out of pre-press. These systems eliminate the need to print film positives while creating high-quality stencils that result in sharper prints. Automation has also made it easier to apply emulsion to screens.

Side-by-Side Digital and Analog Press Technology

Hybrid machines that combine the advantages of digital and analog printing technology make it easier for printers to tackle larger orders. While these machines are currently quite expensive, as the technology continues to improve, they are likely to become more accessible to small and medium-sized shops.

Even traditional screen printing machines are becoming more technologically advanced. Automatic screen printing presses are being designed to save time, reduce waste, and operate more efficiently. Many now feature touchscreens that are easy to operate, and some have features that allow users to save and recall parameters for complete jobs. This drastically reduces setup times.

Some systems are also Wi-Fi compatible and feature self-diagnostics software to simplify maintenance and eliminate downtime. As technology advances, these features are more likely to be found on virtually all systems.