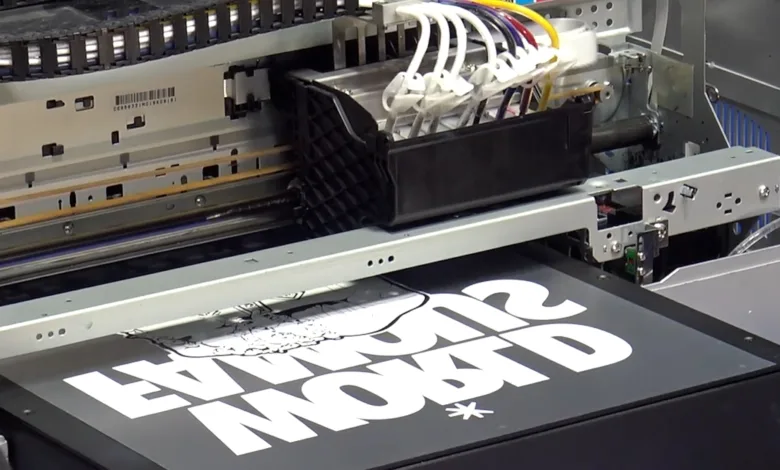

Direct to film, or DTF printing, is one of the newer options to crop up in the garment decoration world. The latest trade show floors are loaded with new DTF machines ready to get people into this fresh new decorating option.

If you work in some aspect of garment decoration or buy decorated garments regularly, you’ve probably heard of it, but you may not know or understand quite what it is and why you’d want to use it. Like with a lot of new things, it takes some time to learn the basics and to decide if DTF is for you. This article will give you some details about DTF printing, what it is, why you might want to use it, and the benefits and minuses, so you can get a handle on this relatively new technique and decide whether or not it fits in with your current products and is something you want to offer.

What is DTF printing?

First off, we start at the basic level. What exactly is direct-to-film printing? As the name implies, a print is made on a film and then transferred, with the use of heat, to a fabric. Unlike sublimation, which requires 100% polyester fabric for the best transfer, or direct-to-garment printing, which generally works best with cotton, DTF prints are suitable for a variety of fabrics. DTF also works on both light and dark colors, so you can print on more types of garments.

One of the things about DTF printing that excites a lot of people is the fact that it can print white ink. For a lot of decorators, white ink is the holy grail because it allows printing on dark garments. White ink is one of the reasons that DTG was so popular when it was first introduced, despite a fairly high learning curve and issues with the inks and printer clogging in some cases. Being able to print white expands the range of designs that can be used and allows shops to sell garments in the colors that a lot of businesses favor.

Keep in mind that a DTF print is essentially a heat transfer, meaning that you will need a heat press in order to seal the print to the garment. If you already have a heat press in your shop, great, you’re set. If not, keep in mind that it is always wise to purchase the largest heat press you can, and to consider the largest-sized garment or item you might be decorating with that press. Keep in mind that, while a no-name heat press from Amazon might seem like a cheaper alternative, presses from reputable businesses like STAHLS’ or Geo Knight will have warranties, maintenance agreements, and tech support. A heat press can be a cornerstone of your shop’s business, so it is wise to invest in one that is well-supported.

Needed equipment

Besides a heat press, you’ll need some other equipment and supplies to get started with DTF printing. One thing, of course, is a printer, which may be called a DTF-modified printer. These printers work with six colors: your standard CMYK and then white in the additional tanks. Also, the printers have special rollers that move the film so that you avoid lines in the white layer being printed on the DTF film.

Since you are printing on film, you will need to keep some in stock. PET films are used and may be called DTF Transfer Films. Most will come in either cut sheets or rolls. They will also have the option of being hot peel or cold peel. This means that the transfer film is either peeled from the garment while it’s still warm, or it is allowed to cool and is then peeled away. As with most things where there are options, decorators have preferences on both sides of this issue. Some people maintain that hot peel transfers can be rubbery and have a textured feel, which may work for some decoration styles but not for others. Cold peel transfers are often more matte in appearance and may have a softer feel. This may be a case where one style of transfer will work best for some things, and another style will work best for others.

As with most printing options for garments, software plays a large part in the process. RIP software is necessary to manage the color profiles of the ink, the characteristics of the print, and the final performance of the print on the fabric. For DTF, the RIP software has to be able to manage both white and CMYK colors. There is also DTF printing software, which is used to manage the machine and help ensure that the final print is optimized to get the best result.

One thing that DTF printing requires that other printing techniques may not is hot melt adhesive powder. This is used as an adhesive to bind the color to the fabric. There are different grades of this powder, which are measured in microns. You will need to have the proper powder based on the requirements of your setup and designs. Another need will be some way to get the powder on the garment accurately and evenly and to remove excess powder. Commercial DTF setups may use an automatic powder shaker. This applies the powder evenly and provides a way to remove any excess.

In order to use the film and adhesive powder, you need to have ink with which to print. DTF printing ink comes in CMYK and white options. The white ink is generally used as a base layer, with the colors printed on top of it in the appropriate places. The ink is printed on the film, and then the adhesive powder is added, which sets the ink into the print. Heat is added to melt the powder. You can use a curing oven or a heat press, the top of which would not be closed or locked. Generally, you would leave a 4 to 7 mm gap between the top of the press and the face of the print. The melted powder becomes an adhesive, and this is what allows the print to stick to the garment. The melted powder essentially acts as a binder and melds the fibers of the garment of choice with the pigments.

Pros and cons

DTF can potentially be a major profit center for a business, but, as with all decoration techniques, there are a few pros and cons to consider. One major pro is that this process uses white ink, which makes it suitable for use with dark garments. It can also be used on a variety of fabrics. These two traits together mean that DTF printing opens up a wide range of garment colors and types to being decorated. While having options when it comes to colors and fabrics is great, obtaining those options comes at a cost, which may potentially be a big con when you’re considering whether DTF printing is for you. While some retailers will make the case that you can cobble together a decent entry-level system for $3,000 or so, heat press included, if you want to enter DTF printing on a professional level, you’re probably looking at a cost of $15,000 or perhaps higher. Now, the potential profit that can be made as a result of that expense may make it worth taking on, but it is a bigger commitment than the start-up costs of some other methods.

Another potential con is that DTF is still a relatively new technology, and the kinks are still being worked out. There’s also a ton of misinformation out there about what DTF is and what it does or will do for you. Yes, there are shops using it successfully and happily. And, equally, there are people selling you a bunch of bull about how easy and fast it is and how quickly the dollars will pile up when you add the process to your shop. As with all garment decoration processes, it’s on the individual who owns the shop, or whoever buys the equipment and selects the processes the shop offers, to maintain their due diligence and make sure they get good information and deal with reputable dealers.

In the final analysis, DTF printing has a great deal of potential. The fact that there’s no weeding or pretreatment needed is a selling point for some shops. The cost for a professional setup and the possible need for things like an automatic powder shaker and other process-specific equipment may price this decoration option out of the range of some shops, but, in those cases, starting out with DTF transfers may be a less expensive option for entry. DTF printing does work with a wide range of fabrics and color options, which means it offers the ability to print on a larger range of garment types, and that’s always an attractive prospect. As with most new decoration disciplines, the main thing to remember is not to get so excited about the possibilities that you forget to research all sides of the issue and learn about the pitfalls as well as the peaks. The story of DTF printing is just starting to be written, and it remains to be seen if it’s a decoration technique that is here to stay or one that is just the fad of the moment. Initial signs seem to be that it has staying power, but the full impact of DTF printing on the industry remains to be seen.