Selecting the right adhesive is critical for the success of many different types of applications and projects. Simply put, if you do not get this choice right, you risk ruining the hard work you put into creating the application, thus putting the entire job and installation in jeopardy.

Initial tack or wet grab, shear strength, optical clarity, color, permanent or removable characteristics, and temperature and solvent resistance all need to be considered when designing a custom tape or adhesive for a specific customer application. If the wrong adhesive is chosen, it can lead to product failures, which can damage the reputation of our customer’s final product.

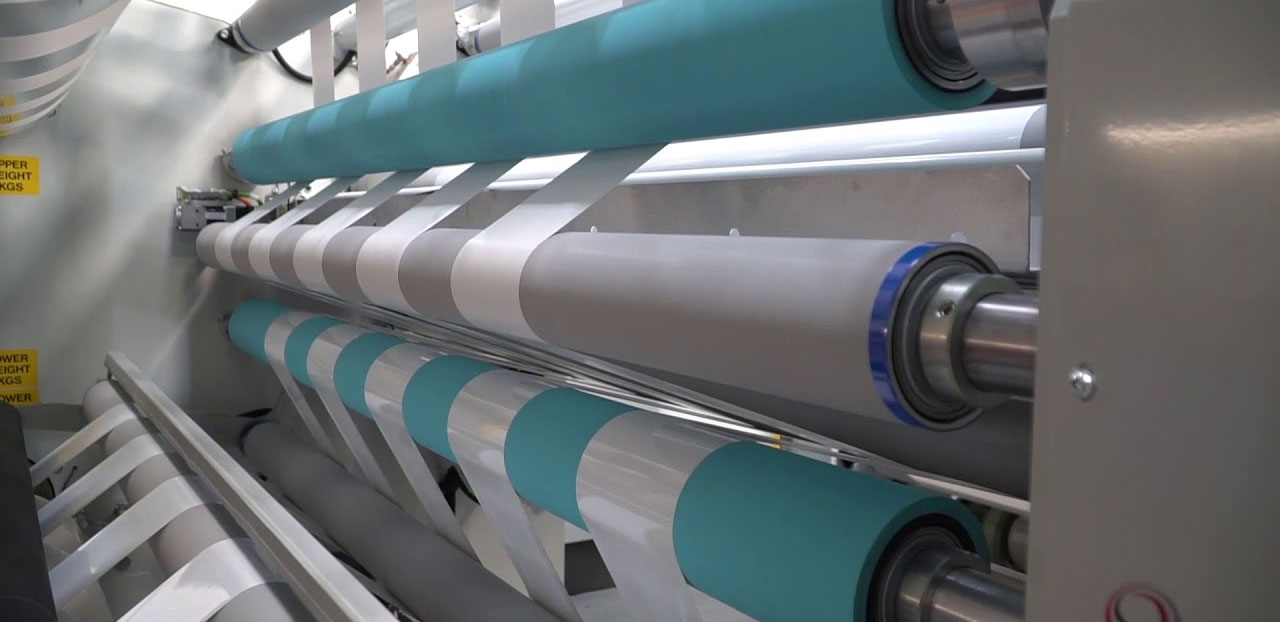

In my role at Drytac, I work in the custom coating side of the business. This covers both signage and print applications, as well as a range of key manufacturing industries like medical, renewable energy, and transportation, where the right adhesive is needed for all kinds of projects.

With that in mind, what should companies look out for when selecting adhesive materials that work?

1. Adhesive quality

First and foremost, you need to consider the quality of the product you will be working with and the reputation of the manufacturer that supplied the material. As is the case with all kinds of material, you get what you pay for, and opting for cheaper, less-known brands can be a bit of a risk.

2. Technical support

Next, do some research into the type of technical support you will get from the tape manufacturer. Not only is the adhesive choice important for the final product, but the other components play just as significant a role. The adhesive carrier and release liner, if required, are critical for the overall performance of the tape throughout the manufacturing process, from coating the material to the converting or fabrication of the product to the final use of the tape in the manufactured component.

3. Customer support

Finally, consider the level of post-sales customer support you are likely to receive from the tape manufacturer. Once the tape is produced and sold, customers need the proper level of support to ensure they receive their product on time every time.

From PSA labels and point of purchase displays to wallcoverings, there’s a perfect self-adhesive product for any application.