The Pros and Cons of Bringing Digitizing In-House

Here are some of the pros and cons of bringing digitizing in-house.

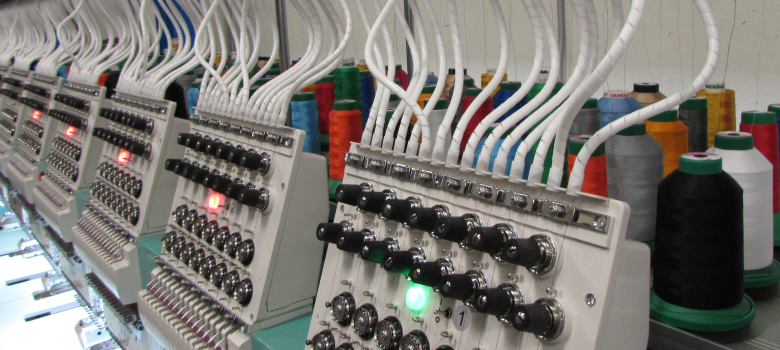

Embroiderers often wrestle with the decision of whether to bring digitizing in-house or outsource the process. The single greatest challenge in making this decision is that many embroiderers do not know the benefit or detriment of bringing digitizing in-house. On the surface, it sounds like a great idea, but it is not for everybody. Taking a structured approach to this process can help you make an educated decision. Following are a series of pros and cons of bringing digitizing in-house.

PROS

For starters, in-house digitizing means you will save on outsourcing fees. While outsourced digitizing has become very inexpensive, companies that do large volumes of work could benefit from bringing digitizing in-house.

Additionally, there is no higher level of control of the digitizing process than having it done in-house since you’re not at the mercy of someone else’s schedule. We live in an on-demand environment, and there is nothing worse than watching the pot boil while waiting for an important design. With an in-house digitizer, you have full control of the schedule and the ability to readjust production based on customer needs.

That said, your quality can only be as good as the digitizer(s) on staff. However, quality can be controlled to a certain extent through design editing. In this instance, quality can be focused on as opposed to quantity. Many digitizing companies are simply production houses and do not have the time nor resources to spend unlimited time on a single design. These limitations can sometimes result in a design that does not meet quality standards.

One of the biggest benefits of bringing digitizing in-house is that it provides the freedom to digitize spec samples on-demand. This ability offers the flexibility to visit potential customers and offer a sample swatch or garment for evaluation. While there is an investment of time, it could be a great way to fill gaps between jobs. If you are paying an employee for full time but only have enough work to fill a portion of the day, this is a great way to fill the gap and be proactive toward gaining new business opportunities. If you don’t want to invest in producing an actual sample, I recommend creating an embroidered swatch and then incorporating it into a flyer that you can drop off to the customer. This approach is particularly useful when dealing with a company that does not already have an existing embroidered logo.

CONS

Unless you hire an experienced digitizer, the learning curve can take months or years to get to the skill level of seasoned veterans. Training extends far beyond learning how to use digitizing software. The actual digitizing software is usually the easiest part of the process to learn. The problematic aspect is learning how the combination of thread and tension affect the substrate that’s up for embroidery.

Additionally, it is the responsibility of the digitizer to create the pathing of the embroidery machine. The digitizer controls every movement of the embroidery machine including travel path, trims, color changes, underlay, and density. The best training approach is to expose a digitizer to all aspects of the embroidery process.

A quality digitizing system can be expensive. In some cases, the software can have a higher price tag than an embroidery machine. Remember, a digitizing system is an investment. When calculating the ROI of the purchase decision, be sure to factor in the cost of hardware, software, labor, and training.

While quality control is a reason to consider bringing digitizing in-house, it is essential to remember that the limitation of the result lies within the person creating the design.

Additionally, there are many digitizing sources capable of handling large volumes of work. An in-house digitizer can only produce so many designs in a day. To reach high-volume requirements in-house, it may require multiple digitizing systems and multiple people employed as digitizers. Keep in mind, when there is turnover, the selection, training, and learning curve process begins all over again. This can have crippling effects, especially for a small company.

In terms of a time commitment, it only takes a couple of hours of in-house work to equal the cost of outsourcing. There becomes a point where it is merely not feasible to do designs in-house. This, of course, is in direct relation to the person digitizing as well as the quality of the end result. Receiving a piece back from an external source that is not top quality is not justified at any price.

For insight on when it’s a good time to transition to in-house digitizing, check out this Q&A.