One of the many keys to quality control is to control the variables of the process from start to finish. Here are some of the more overlooked variables within the process which have a direct impact on the quality of your finished product.

SCREENS

Screens are one of the primary keys to producing a quality print in textile embellishment. The quality of your finished product is directly proportional to your finished print-quality in, quality out. Of the many variables related to the screen, tension is typically the most overlooked. As it is the frame that dictates and controls the overall tension, retensionable frames allow for the greatest degree of control and stability. Whereas static frames (aluminum and wood) only allow the screen to decrease in tension over time, retensionable frames allow you to work harden (stabilize) the screen’s tension allowing for higher quality printing from numerous points.

PRESS CARE

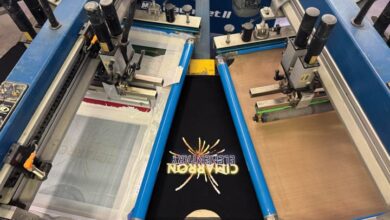

An additional critical point to address regarding quality control is proper maintenance and care of your press(s). Many people place a new printer in their facility and run them until something goes wrong then wonder why. One good rule to follow here is to avoid mist spray adhesives, which work their way into every nook and cranny of the press their lint builds up throughout. A good liquid platen adhesive can last longer, cost less with no adverse effects to your equipment.

Another aspect of press care that often goes overlooked is the screen/platen parallelism. To maintain good quality, you need to ensure that your presses (manual or automatic) maintain the correct screen off contact and screen/platen parallelism to ensure a uniform and quality print from platen to platen and shirt to shirt.

THE DRYER

Another overlooked aspect of many shops is the day to day condition of the dryer(s). As with any piece of equipment within your facility, you should have a regulated preventive maintenance program to ensure you maintain proper and consistent curing temperatures within your dryer chamber. This includes regular cleaning for filters (on gas dryers), lubrication of any moving parts or rollers and a standardized (daily) temperature check. Any standard means of monitoring your dryer’s temperature is better than no standard at all. This includes the use of heat tapes, non-contact pyrometers, or donut probes. Of the three, the donut probe is best for identifying cold spots due to a bad heating element or clogged air knives in a gas-fired dryer.

SQUEEGEE CARE

When it comes to overlooked Q.C. procedures, squeegee care must lead the pack. It is the squeegee that controls the actual transfer of ink from the screen to the surface of the fabric. It’s a challenge to not find a parts cleaning tank in most any textile screen-printing facility that does not have some used squeegees in it waiting to be cleaned. What is not considered by most is that over time, the squeegee blade will absorb solvents and begin to warp and swell over time. Squeegees are made to be utilized for a production run, cleaned immediately after the production run, and racked or cycled for the next order. Proper care or your squeegees will yield a much longer life, high performance and cost savings over time.