Punch N Press: An Easy, Inexpensive Way to Grow Your Business

Looking for an inexpensive, versatile, easy moneymaker to add to your business?

About this Sponsored Content

Johnson Plastics Plus, headquartered in Burnsville, Minnesota, has been a leading supplier to the engraving and sign making industry since 1970. Our Johnson Plastics Plus commitment to serving the needs of the engraving, sublimation and sign making customers remains our primary focus. Visit www.jpplus.com for more information.

Looking for an inexpensive, versatile, easy moneymaker to add to your business? Check out Johnson Plastics Plus’ Punch N Press. The Punch N Press system works with any standard color printer. Once you’ve got your Punch N Press, you’ll be making full-color items in no time. With a variety of products available, the easy to use Punch N Press will give you endless personalization possibilities to offer your customers.

One of the benefits of the Punch N Press system is that there’s almost no learning curve. As you’ll see below, it’s very simple to get started. The portability of the system also means you can easily take it on the road to sporting events, craft shows and company picnics. As long as you can plug in a laptop and a printer, you can make Punch N Press items right on the spot.

Starter kits are as low as $299 and additional blanks are less than $1 each, so you can easily pay off your initial investment with the first order. Personalized photo keychains can go for up to $30 on Etsy… meaning there’s lot of profit margin with this product line. You only need one Punch N Press base, then purchase the swappable cutting and assembly tools for the items you want to sell. We also provide free templates on jpplus.com for easy sizing and printing of your inserts.

How It Works

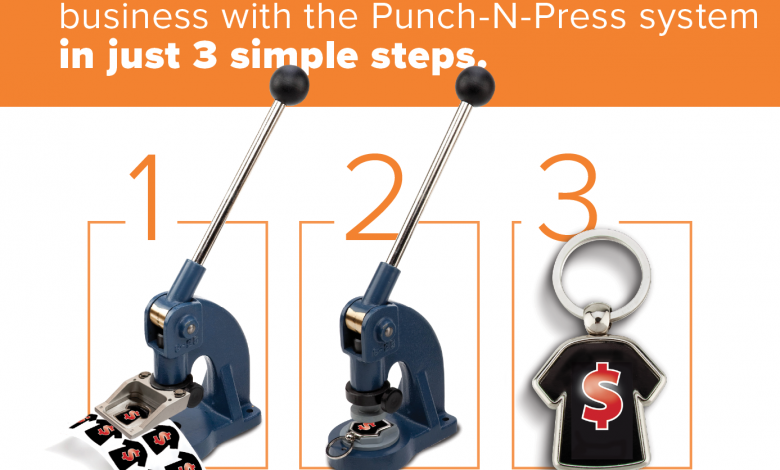

The Punch N Press system is easy to use. You can create any of the Punch N Press items in three simple steps:

Three simple steps to making Punch N Press items.

- Print your inserts using any printer on any type of paper. We offer free templates at jpplus.com to make creating the inserts easy.

- Punch out your insert using the specialized cutting tool designed for the item you’re selling. The cutting tools ensure you’re getting a precise insert for each item.

- Press the clear acrylic lens over your insert using the assembly tool.

With these three simple steps, you’ll have a full-color item to offer your customers. For two-sided items, you can mass-print a logo on one side and add personalization (such as a name or jersey number) to the other side.

What can you make with the Punch N Press?

We offer an ever-expanding array of products for the Punch N Press, including keychains, magnets, name badges, lapel pins, and lanyards. Made from metal or high-end acrylic, the Punch N Press items look and feel like a quality product. All products can be created with the three steps above, although some name badges can be assembled by hand.

A selection of Punch N Press items.

Selling the Punch N Press products

With the versatility of the products available, the Punch N Press can be geared toward almost any market.

For example, house-shaped keychains are ideal for realtors to use as open house giveaways, and the black leatherette keychains can give car dealerships a giveaway that have a high-end look and feel. The sports-shaped keychains, with an insert on one side and an imprinted ball on the other, are perfect as fundraisers schools or clubs. And finally, the Punch N Press name badges are an easy, inexpensive way to create full-color badges for any industry.

Punch N Press items are ideal for your customers to use as give-a-ways or fundraisers.

To learn about all that you can do with the Punch N Press system, download our free brochure at JPPlus.com.