Expand Your Business With UV-LED Printing

Explore the idea of expanding into UV-LED printing in this feature from the July 2019 issue of A&E.

With ever-tightening competition in today’s market, diversification can go a long way in standing out among the crowd, especially in the graphics market. Customers increasingly want one-stop shopping and more personalization, and many awards and engraving shops already have the graphics skills to provide an expanded product line from the typical offerings.

But how do you expand your business line and capabilities without investing in too much equipment and losing valuable shop space? That’s where UV-LED printing can help.

Why UV-LED Printing?

Essentially, UV-LED printing is designed on the same premise as your standard inkjet printer, says Rachel Tindal, art director of LogoJET. You design your imprint in graphics software, place your printable item on the adjustable flatbed, and press print. Once the ink hits the substrate, the LED light on the print head instantly cures the ink, so you’re left with a print that requires no drying time.

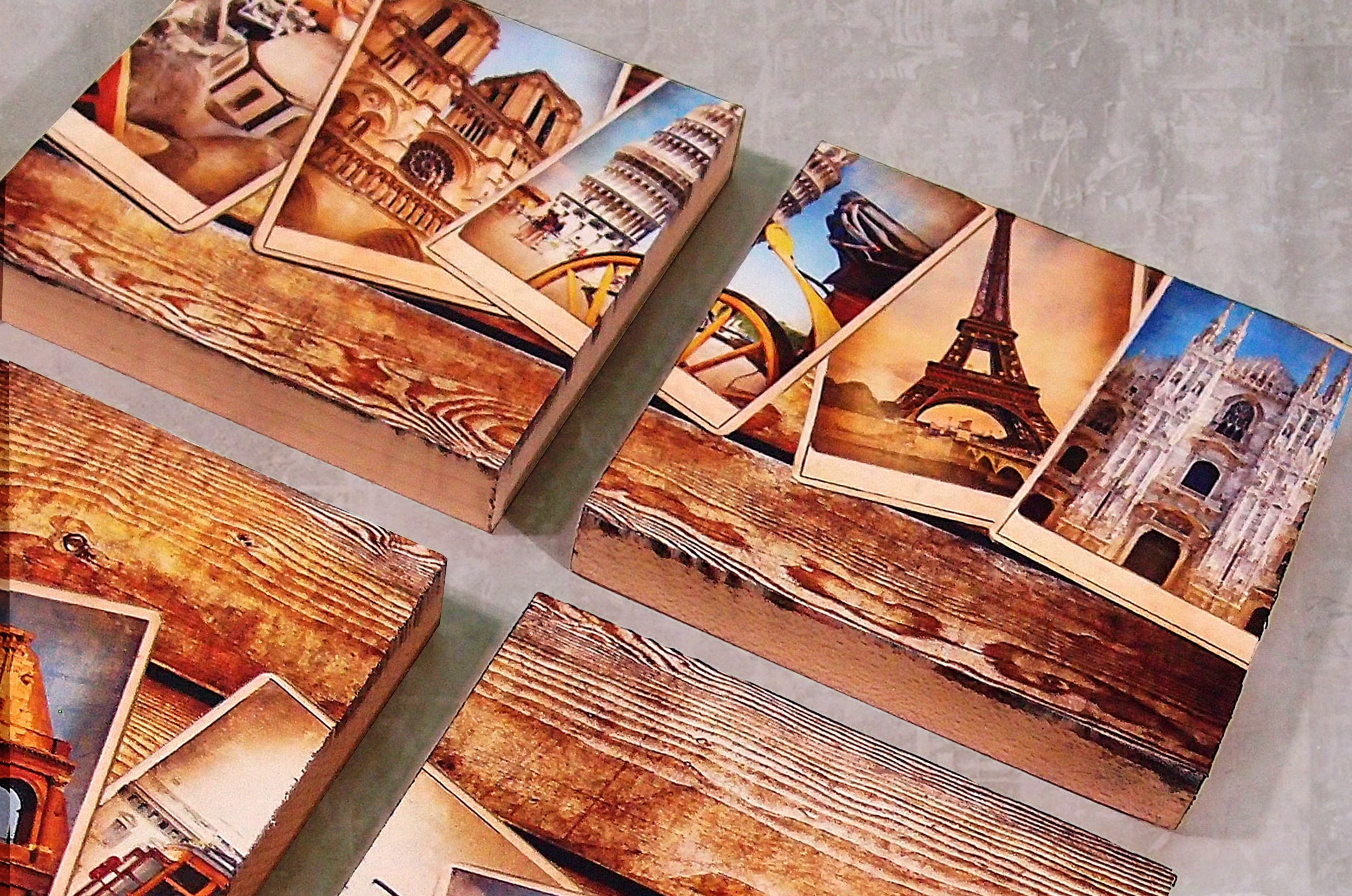

With no drying time, the printing process is more efficient, and it protects the material from deforming, says Keira Lee, marketing manager of GCC. UV-LED printing is compatible with a variety of substrates, including vinyl, acrylic, wood, and metal, and it can print onto 3-D shapes, such as picture frames and water bottles.

UV-LED printing works with a variety of substrates, including vinyl, acrylic, wood, and metal. (Image courtesy GCC)

Not only is the print immediately ready to go, but the resulting finish is also in full-color and can be combined with other technologies to create custom products, says Don Copeland, product manager of UV printing for ColDesi. For instance, laser engraving is often used to complement UV-LED printed products. An awards shop can shape a piece of acrylic into that of a football, add the laces using the laser engraver, and then print color onto the acrylic.

“Laser engravers are the most common piece of equipment for almost every awards and recognition shops these days,” Copeland believes. “With UV printing, you can take that blasé rectangular shape of acrylic and turn it into a customized award that’s more valuable to your customers.”

Along with UV-LED printing’s full-color and custom capabilities, its versatility is also a major benefit to awards and engraving shops and allows for greater diversification, says Michael Perrelli, marketing manager of Direct Color Systems (DCS). While a UV-LED printer can certainly create most awards and engraving shops’ typical product lines, it can also produce signage, all sorts of promotional products, and even T-shirts. These products may be outside of your current offerings, and sometimes getting out of your comfort zone is scary for a business. But for those shops willing to incorporate new markets into their offerings, it could open up more opportunities.

Incorporating UV-LED printing into your business is a great way to expand your offerings as it complements other technologies and allows you to offer full-color products. (Image courtesy ColDesi)

“Some shops may be hesitant because they think, ‘That’s not us,’ but business evolves,” Perrelli points out. “You don’t have to turn your back on your awards business to chase signage or promo products, but know that people who are buying awards are also buying those other things as well. Make sure your customers buy those products from you.”

How to Get Started

Generally, everything you need to get started comes with your initial UV-LED purchase, including the ink and software, and the typical cost of entry is around $22,000 for a tabletop UV-LED printer, Copeland says. Large, wide-format printers can run much higher, but a tabletop unit is a good option for awards and engraving shops.

While an out-of-the-box UV-LED printer is enough to get started, optional attachments are also available, Perrelli says. These attachments include a vacuum table for holding the material flat and stationary, as well as jigs for printing on water bottles and T-shirts.

Adding UV-LED-printed signage to your offerings is a profitable way to diversify business. (Image courtesy ColDesi)

Of course, like any new piece of equipment, you need adequate shop space to accommodate the machinery, but this often isn’t a problem even if space is tight. Many UV-LED systems in awards shops are tabletop units that need about 3 feet by 3 feet of space, Tindal says. These printers are compact and don’t come with a lot of peripherals, so it doesn’t take much space to store a unit.

When carving out space for a new UV-LED printer, keep in mind that it should be in a clean, climate-controlled environment and protected from humidity, Tindal advises. You don’t want any dust or dirt getting onto your printed material or in the machine. “A UV printer isn’t something you want to keep back in the shop with your sandcarving equipment because it’ll get dirty,” she continues. “You want to treat this like a high-end piece of equipment rather than just a workhorse.”

Like almost any new application, beginners should expect to face a learning curve, Tindal says. Most manufacturers offer on-site training for the software and production upon installation, which should be enough to become functional. However, developing expert-level skills in UV-LED printing takes time because of its customable nature.

“There’s a lot of trial and error to find out which print settings work best for which substrate,” Tindal states. “Your training technician will go through the types of projects you’ll most likely handle, but there will be bumps in the road as you continue to experiment.”

As you practice on new substrates and items, Copeland recommends keeping a log for reference. Record the type of substrate, whether you used an adhesion promoter, and your print settings. By keeping a log, you won’t have to waste time and materials when that same project comes up in the future.

While the initial training is enough to equip awards shops to produce right away, Lee estimates that an operator with design experience can become truly proficient in about three to six months.

With UV-LED printing, you can create textured effects for a more high-end finish. (Image courtesy GCC)

Get the Most Out of Your UV-LED Printer

Of course, getting the best prints for your business starts with choosing the right printer. In Perrelli’s mind, there’s no substitute for seeing the printer in action and asking for printed samples before you buy. You need to understand what it takes to set up a file and print in a real environment, and see the output firsthand.

“The back of a spec sheet tells the story, but it’ll always be the best-case scenario,” Perrelli says. “All too often, people will just see a video and buy the machine. It doesn’t hurt to pause the buying process to get some samples printed, whether that’s at a show or directly sending a request to the manufacturer.”

When it comes to the printing process, it’s generally the same for most applications because it’s digitally set up, but there are a few variables to keep in mind. Depending on the substrate, certain surfaces are trickier to print on, such as glass and uncoated metals, Tindal says. In those cases, an adhesion promoter can help. “Usually, these adhesion promoters are just a liquid you wipe onto the surface and allow to dry before you print,” Tindal offers. “It creates a more porous surface to accept the ink. Some printers actually include a primer ink built right into the system, so we’d recommend using that layered in to increase adhesion.”

UV-LED printing isn’t just for flat surfaces. 3-D objects, such as tumblers, are also compatible. (Image courtesy LogoJET)

The type of ink used can also vary by substrate, Perrelli adds. For a glass or metal surface, you don’t have to worry about the material bending. However, that’s not the case if printing on a fabric or leather. When those situations arise, Perrelli recommends printing with a flexible ink rather than the rigid ink that you’d use for glass or metal. (Editor’s note: Read more about ink sets in the UV Printing article featured in the January 2019 issue of A&E, page 8.)

For those shops looking to diversify and gain that competitive edge, UV-LED printing is an option to consider. With its customization and full-color capabilities and versatility, this technology allows awards and personalization businesses to better serve customers by catering to their many needs.

Printing photos is an effective way to add more customer value to your product offerings. (Image courtesy LogoJET)