Chemical Etching: What It Is and Why You Should Care

Recent advances in technology and the development of new techniques is taking this once niche manufacturing technique into the mainstream.

Chemical etching is one of the most commonly outsourced processes in the sign and awards industry, often with long lead times. However, recent advances in technology and the development of new techniques are taking this once niche manufacturing technique into the mainstream. In this article, we’ll explore the benefits of adding the process to your business and how your existing equipment could help get you started.

What is chemical etching?

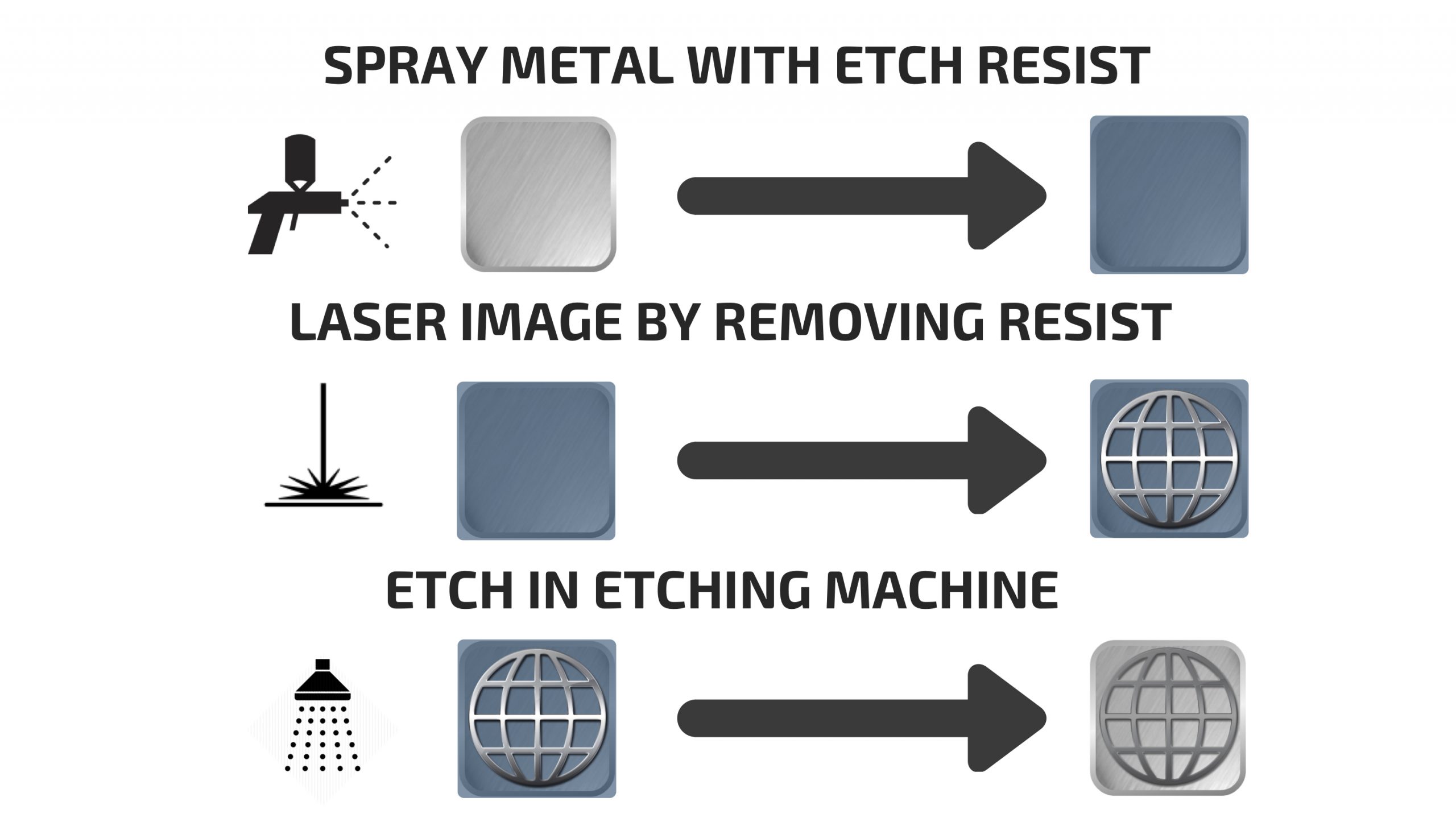

Chemical etching is a method of engraving that uses a high-pressure temperature-regulated chemical spray to remove material to create a permanent etched image or shape in metal. A mask or resist is applied to the surface of the material and is selectively removed, exposing the metal, to create the desired image. The material is then placed in an etching machine, typically a conveyorised machine consisting of an etch chamber and a rinse chamber.

An etching machine harnesses the corrosive reaction between the chemical and the material and amplifies the effect by heating the solution and spraying at high pressure. The chemical spray dissolves the unprotected metal areas to etch the material. The depth of the etch is controlled by conveyor speed. A slower pass results in a deeper etch whereas a faster pass produces a shallower etch. After etching, the resist layer is removed.

The most commonly used and least hazardous etchant is Ferric Chloride (FeCl 3 ). Ferric Chloride etches stainless steel, brass, bronze, copper, nickel, aluminum, and more. It’s a versatile chemical that’s widely available and inexpensive. There are a few materials it won’t etch. Due to their physical properties, magnesium and zinc require an entirely different processing method, while the chemistry required to etch titanium is extremely hazardous, and few companies have the capability to do so.

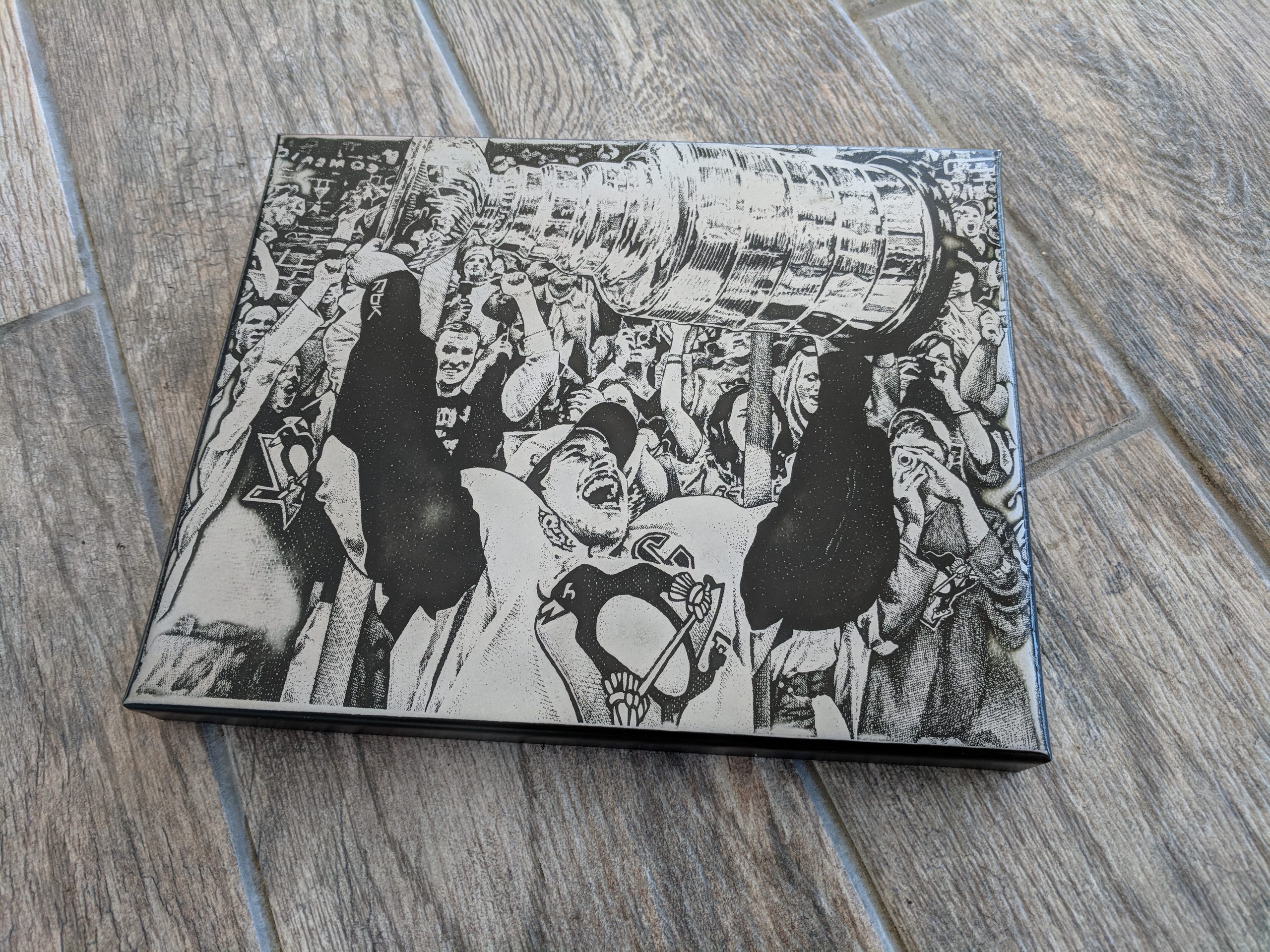

Chemical etching is a method of engraving that uses a high-pressure temperature-regulated chemical spray to remove material to create a permanent etched image or shape in metal. (Image courtesy Liam Dullaghan Jr.)

Benefits of chemical etching

The main advantage with chemical etching is that it etches the whole surface area of the material at the same time. A laser has to mark each area individually, often making many passes to achieve tangible depth. With chemical etching, the amount of detail and size of the etch area have little effect on the process time. This means that it’s possible to deep etch even large and complex designs in minutes.

Etching is a non-contact process. The material is dissolved atom by atom, producing a smooth burr-free finish and leaving the material grain structure unaffected. There is no heat distortion as associated with laser processing, and no tool wear similar to what occurs when processing hard metals such as stainless steel by mechanical engraving methods.

The increased etch depth makes color infilling straightforward, allowing for the reproduction of logos and insignias. Another advantage with working with real metal is the variety of materials and finishes available, ranging from mirror-finished stainless steel to aged and distressed brass.

Etching has many varied uses within the sign and awards industry including outdoor and indoor signage, memorial plaques, industrial nameplates, offshore and oil signage, awards, medals, custom gifts, jewelry, and much more. The quality and permanency of etched metal make it an ideal solution for a wealth of applications. Chemical etching is also widely used in the production of printed circuit boards and the production of precision thin metal components for use in the electronics, automotive, and aerospace industries.

Dry film method

The most common method of etching is called photochemical etching. In this process, the material is cleaned and then laminated with a UV-sensitive photoresist. A photomask is created by printing the artwork as a negative onto a clear piece of film. The photomask is placed on top of the material in an exposure unit, and a vacuum is drawn to ensure contact between the photo tool and the metal plate. The plate is then exposed under UV light that allows the areas of resist that are in the clear sections of the film to be hardened. After exposure, the plate is “developed,” washing away the unexposed resist and leaving the areas to be etched unprotected.

Photochemical etching is a process that has stood the test of time and consistently delivers excellent results. It can reproduce extremely fine detail. However, it can require a big commitment of space and additional equipment to get started. One way around this is to use your existing equipment to handle the artwork portion of the process.

Laser method

Using a laser to create the mask is one of the simplest and easiest ways to get into chemical etching. This process has become more refined over recent years, and it’s now possible to achieve results on par with dry film, crucially matching both the level of depth and detail.

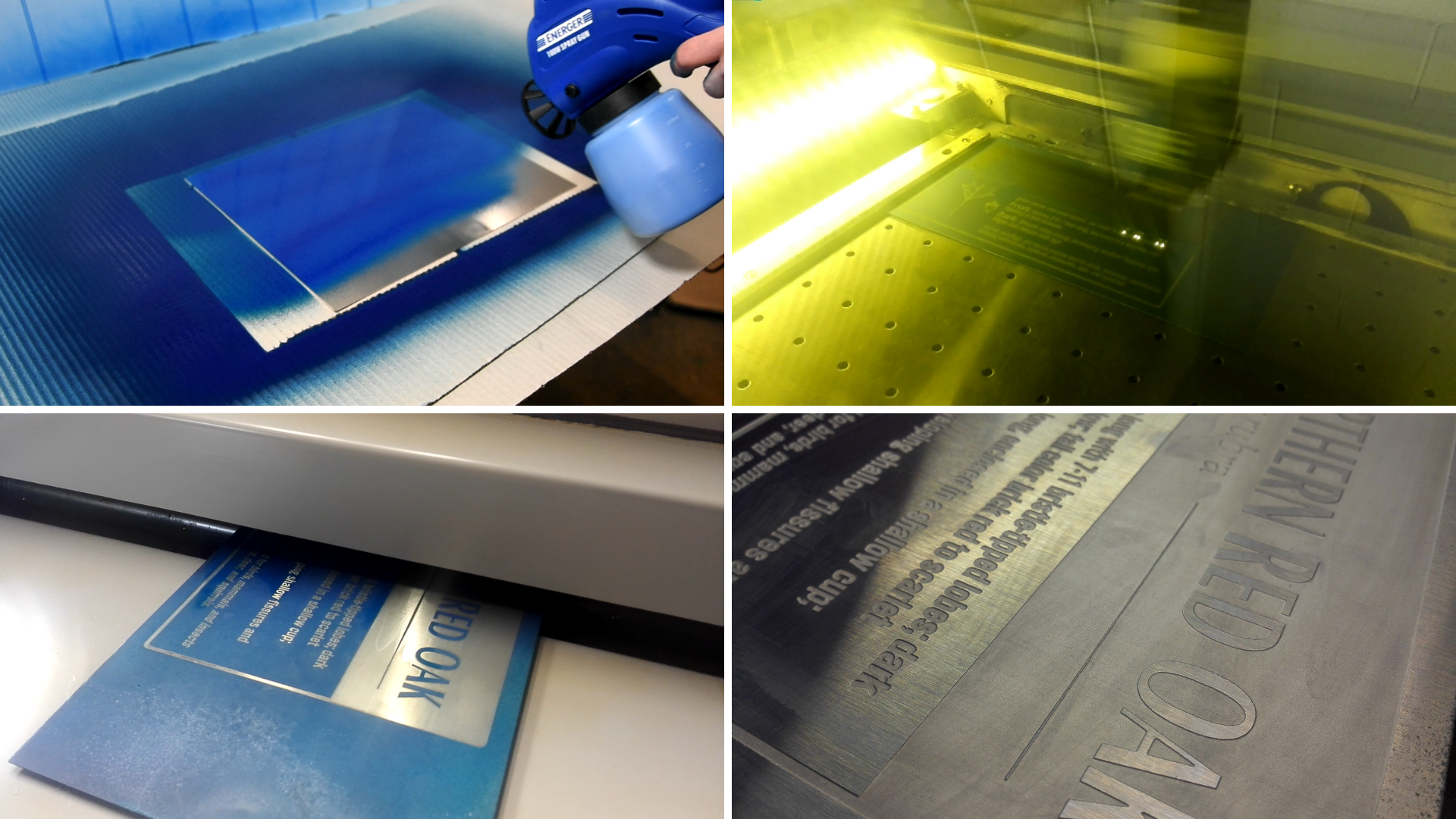

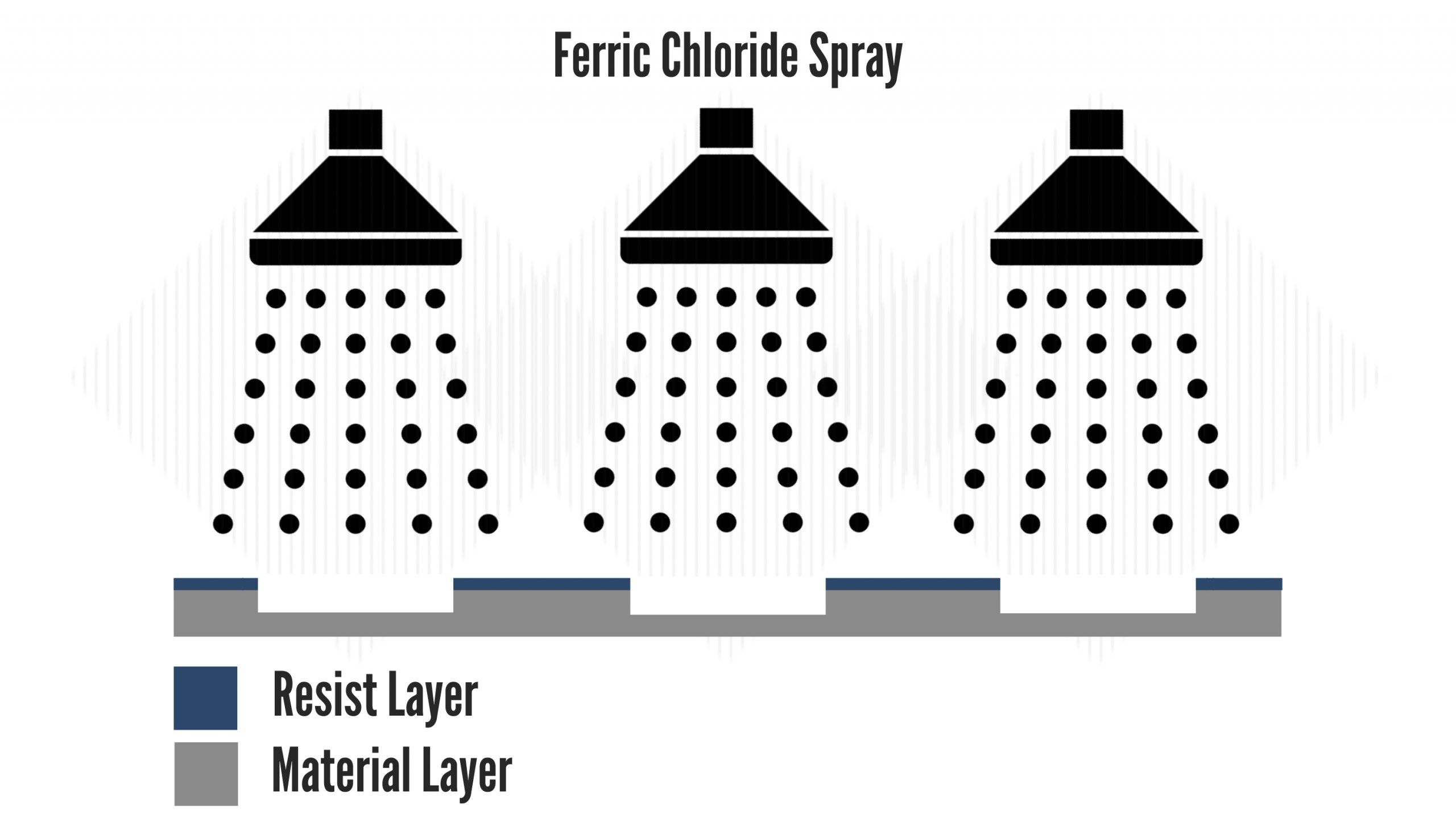

The material is spray-coated with a laser engravable etch resist, which is then cured in an oven for 15 minutes at 150 F. Once dry, the material is ready to engrave. The laser removes the resist layer, exposing the bare metal underneath, to create the mask. The material is then ready to etch.

This process is compatible with both CO2 and fiber laser wavelengths, although settings will vary from system to system. This process is a good option for short- to medium-sized runs and for producing serialized and variable data products. It’s also a great way to chemically etch objects that would be difficult to process using dry film, which is typically restricted to flat items.

Using a laser to create the mask is one of the simplest and easiest ways to get into chemical etching. (Image courtesy Liam Dullaghan Jr.)

Screen printing, vinyl, UV-LED

All Mimaki UV-LED flatbed printers are capable of printing an etching mask using UV inks, from the A3 format UJF-3042MkII to the Grand Format JFX200-2531. Cured UV-LED inks are acid-resistive, making them an effective alternative mask option. Digitally printing the artwork directly onto the material simplifies the etching process greatly. It is also possible to use the printer to color infill the etched areas after etching.

Screen printing is another option for chemical etching. There are a number of screen-printable etch resists available that can be printed directly onto the material to create the mask. This method is ideal for high-volume production and is widely used in the manufacture of industrial nameplates. Vinyl can also make excellent etch resist and is particularly useful for processing large pieces that are difficult to image by other means, although the amount of detail achievable is limited.

Final thoughts

As with working with any chemical, it’s always important to wear protective clothing and follow all handling guidelines. It’s important to also dispose of any used chemical safely and in compliance with all local laws and regulations. The life span of the chemical bath is ultimately dependent on the amount of etching you do. Over time as metal is deposited into the solution, it will gradually lose its strength. Fresh chemical can be added to compensate for this. Typically you can expect to have to change the solution entirely every six to 12 months. As a good rule of thumb, you can expect to pay roughly the same to get your used chemical taken away as it cost to buy initially. Depending on the size of the room where you are carrying out your etching, you may also need to consider fume extraction.

It’s often said that etching is more of an art than a science, which is fitting as many of the techniques still in use today owe a debt to the pioneering work of the Dutch master Rembrandt. It’s a rewarding and creative process with endless possibilities. Chemical etching is a great way to increase your range of products and services while utilizing the skills and equipment already at the heart of your business.

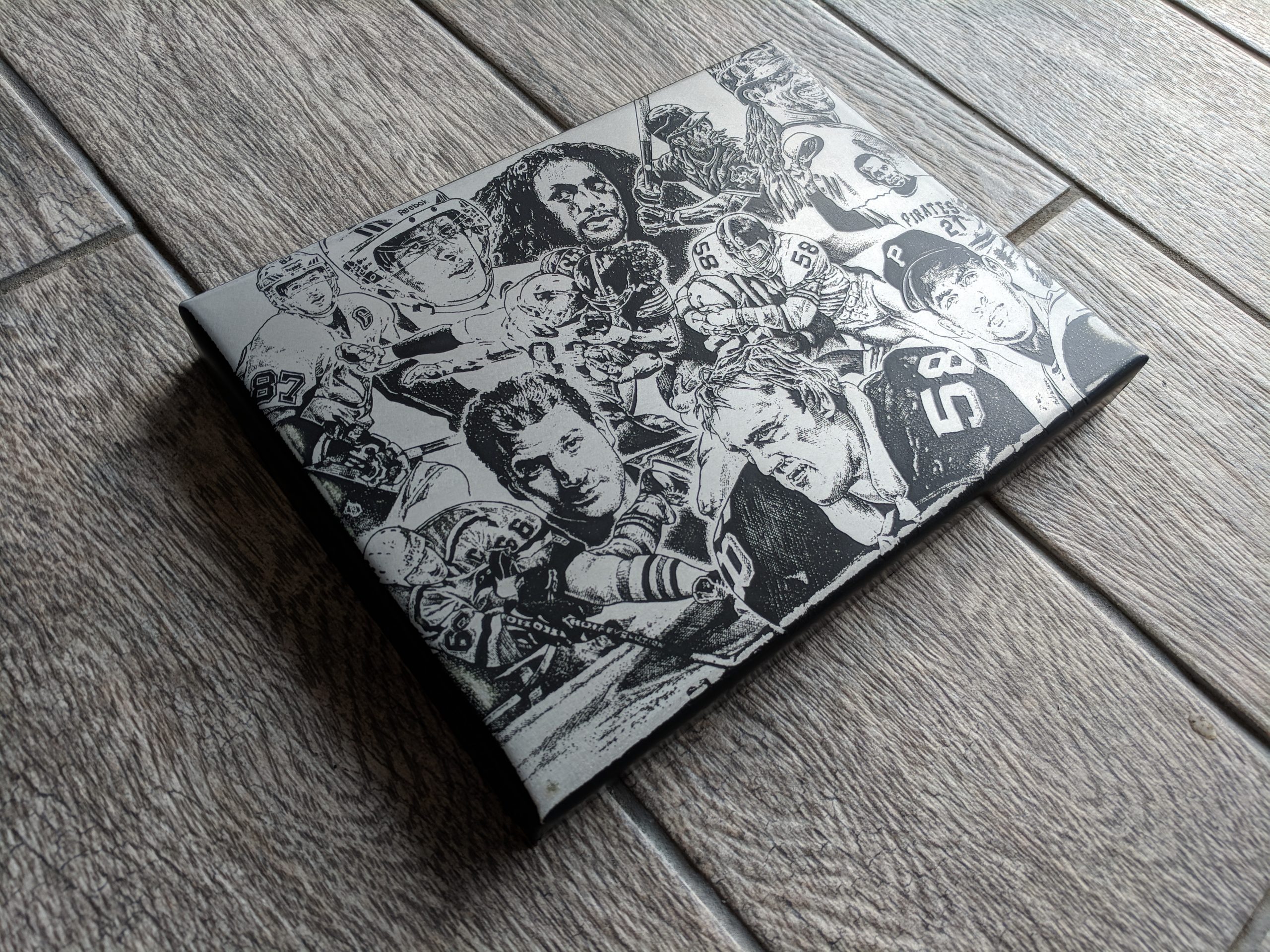

It’s often said that etching is more of an art than a science and is a great way to increase your range of products and services while utilizing the skill and equipment you already have. (Images courtesy Metal Photo Service in Wall, Pennsylvania)