It is important to replace the sandcarving nozzle after it has worn 1/32 of an inch. Replacement is not mandatory, but the worn nozzle uses more compressed air, the abrasive impacts the part more aggressively, and if the air compressor is marginal, the machine controls won’t operate properly unless 90 PSI line pressure is maintained. As the volume of air and abrasive increases, it creates additional wear on the blast hose, too.

The easiest way to know if your nozzle requires replacement is to keep a 1/8-inch drill bit nearby (or a 5/32-inch drill bit if your sandcarving equipment was purchased with a 1/8-inch nozzle). If the drill bit fits into the blast nozzle, then it is time to replace the nozzle.

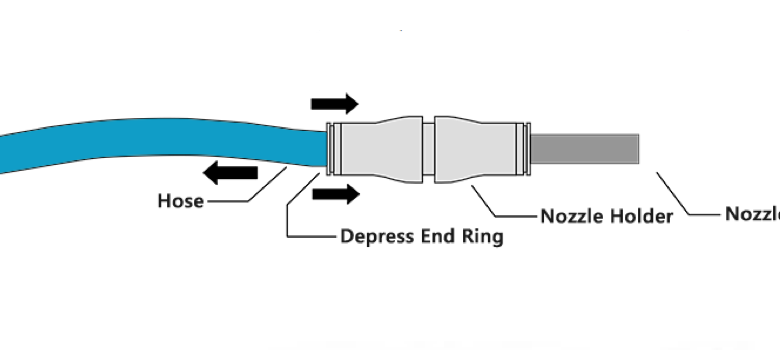

Before attempting to replace the blast nozzle, remember to depressurize the pressure pot during any machine maintenance. To get started, hold the nozzle and nozzle holder in one hand and the blast hose in the other hand. With your thumb and forefinger, press the end ring of the nozzle holder towards the nozzle. As you are pressing, pull the abrasive blast hose in the other direction using a twisting motion. The hose should release from the nozzle holder.

It is important to note that you should not try to remove the nozzle from the nozzle holder. The nozzle holder is designed to be an integral part of the nozzle. Removal and reinstallation of the nozzle into the nozzle holder may cause the nozzle to become a projectile. Injury may occur as a result. Dispose of the nozzle holder with the nozzle when the nozzle has worn out.