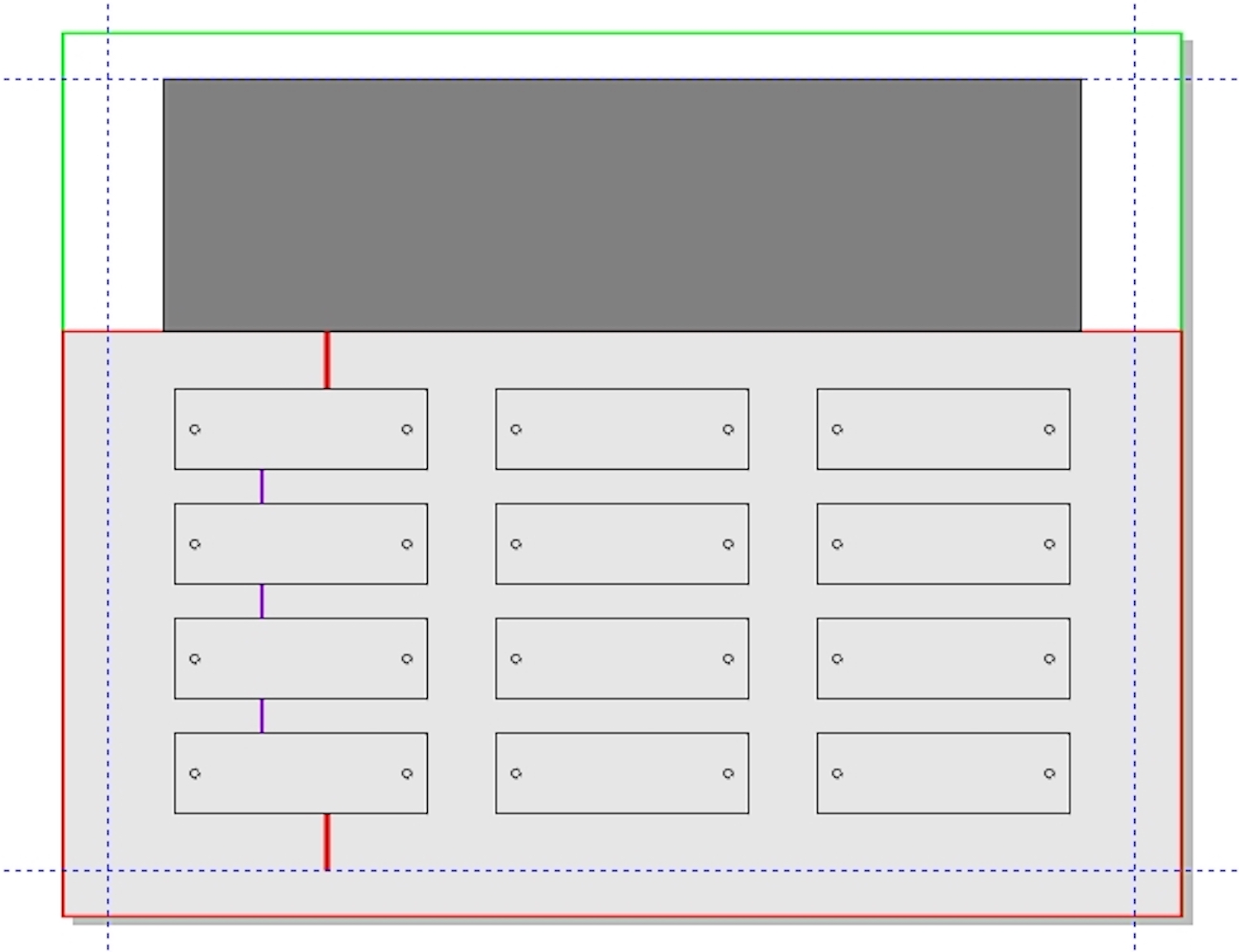

The design and layout of perpetual plaques can vary widely. Make sure you have a thorough understanding of the client’s needs.

CorelDRAW tools make laying out the perpetual quick enough to test ideas or make a final layout. Consider these design and layout tips when working in your graphics software:

- When measuring base product, make sure you measure the flat portion of the plaque or trophy base as well as the overall measurements. Margins should be measured from the edge of the flat section.

- Ideally, leave a 1/2-inch or larger margin around a plaque and a 1/4 inch around a trophy base.

- Know whether plates will be permanently placed or necessitate rotation to other positions.

- Plates that are permanent can be tape-mounted and require an outline for placement by the client.

- Plates that will be removed or rotated require holes, screws, and plaque pre-drilling.

- When possible, use off-the-shelf plaque plates – making metal plates is time-consuming. (Odd sizes may require custom manufacturing.)

- Try to select your perpetual plates before beginning the design. Plaque size can be adjusted if necessary. Include the plate holes in your graphic representation of the plates – you’ll appreciate this effort later when making a drilling template.

- For trophy bases, use 1/32-inch engraving acrylic to make the small plates required. Design without screws if possible.

- Precision of plate placement and application is critical.

- For perpetual plaques that have permanent plates, you need outlines to guide clients when placing a plate on the plaque. The best way to create this guide is to create a backplate for the perpetual plates. The backplate has the engraved outlines, which can be slightly smaller than the perpetual plate so the lines disappear.