Featured Project: Hitting It Out of the Park

Mo Flint, owner of Atomic Barn Studios, says he found Coastal Enterprises' TSF-45 textured surface coating to be perfect for this job.

This project was sent in by Orange, California-based Coastal Enterprises, manufacturers of Precision Board HDU used in the signage and tooling industries. One of its clients, Atomic Barn Studios, based just outside of Raleigh in Willow Spring, North Carolina, used the company’s Precision Board product to create a colorful dimensional sign for a local athletic club in his area.

Mo Flint is the owner of Atomic Barn, which has been around for a quarter-century and specializes in 3D signage. Flint had this to say about using Coastal Enterprises’ Precision Board HDU and TSF-45 textured surface coating:

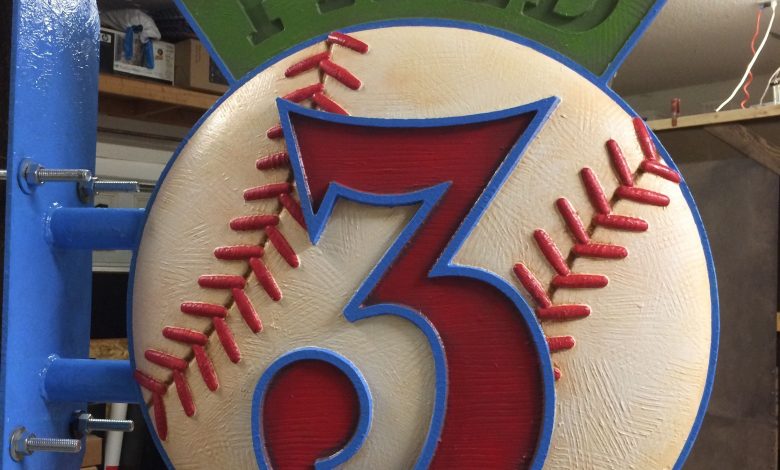

“Poor field No. 3 at our local athletic association’s baseball complex has been without a sign for at least as long as my son has been playing ball there. So, when the fall season donation drive came around, we knew exactly what to contribute-a major-league worthy, classic Americana 3D sign they couldn’t get anywhere else.

“I started with a few different concept sketches until the perfect design revealed itself: a slightly used baseball behind an oversized, easily visible number ‘3’ topped with a grassy green ‘field.’

“With the design in hand, I set to creating a 3D model in Geomagic Freeform. The final sign would be made from three layers of 2” thick, 30-pound Precision Board HDU with steel tubes sandwiched in the center. The number ‘3’ was hand drawn with a raised border to give it some definition. Rather than mirror the stitches for the back they were laid out to line up and flow in the same direction as the front.

“Texture is expected around here and this sign has it in spades. I had been wanting to try TSF-45 for some time and this was the perfect project for it. Instead of adding texture at the 3D stage, I added it to all surfaces, including the steel mounting plate and tubes, after assembly.

“Once the 3D work was done, the pieces were rough cut on the CNC with a ½” ball end bit. The finish pass was cut with an X-Edge tapered bit with an 1/8″ ball end (XTC518) which gave ample detail. When the mounting plate was cut and welded up, it was glued in place before the whole assembly was glued, screwed and left to cure. Sculpting epoxy was used to fill screw holes and finish around mounting tubes.

“TSF-45 was applied directly to the Precision Board urethane foam and over primer on the steel. I used a shop-made tool to comb in the crosshatch texture. The real fun came when the glazes were applied over several layers of discreet base colors. They really add depth and character to the sign.

“In the end, the installation went smoothly with two U-bolts to hold everything in place. A shop name plate painted to match the sign was added just below to wrap up the ‘Field 3’ project. This sign will be a beacon for our athletic association’s Field 3 and its all-star players for years to come.”