Advances in Modular LED Display Technology

Dramatic improvements are making modular cabinets an industry standard.

The concept of billboards has broadened from the printed sign along the highway to now include “spectaculars” and LED displays that push the limits of sign design and technology, adapting products to specific environments and myriad applications. The use of LED displays and modular LED cabinets allows designers to expand the limits of traditional billboard ratios of 12′ x 24′ and 14′ x 48′ to meet customers’ ever-changing needs.

Current cutting-edge digital billboards and spectacular displays show dynamic content, live video, social media and traditional advertising. They can change with the click of a button, adapting to any audience and are becoming an industry standard.

Why Modular?

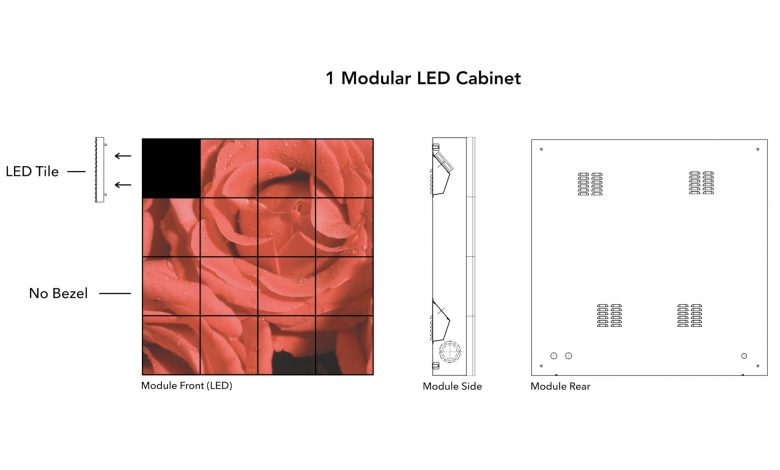

A modular LED display cabinet is defined as an independent unit that can be combined to create a more complex structure, such as a complete LED display or sign. Building displays with modular cabinets provides many benefits, such as increased efficiency, higher quality, more consistent manufacturing, faster lead times, and greater design flexibility to easily produce smaller signs or massive spectacular displays. The modular designs are also bezel-free and fit together seamlessly like Lego pieces, offering limitless configurations and easy installation. Manufacturing efficiencies are leading to price reductions, especially for large-scale projects, which will lead to greater adoption as more customers experience a quicker ROI.

Visual Improvements

Engineers continue to enhance outdoor surface mounted diode (SMD) LED technology for finer pixel pitched applications. These includes increased brightness, advanced weatherproofing and better color uniformity to create a more impactful viewer experience.

Fine pixel (higher resolution) pitch SMD LED displays are the future of outdoor digital signs. Just a few years ago, an SMD outdoor LED display with a 6.667mm pixel pitch was impressive. However, this past year at ISA, attendees saw the next-generation outdoor displays with a tighter pixel pitch of only 3.9mm. Recall that the lower the pixel pitch number, the closer together each pixel is, meaning that higher resolutions are possible.

Additionally, there are indoor products with a very low .95mm pixel pitch and visuals that look crisp-even from just a few feet away. This is becoming necessary because LED displays, billboards and spectaculars are now in closer proximity to pedestrian traffic and require even higher resolution.

These technological advances allow for tremendous versatility in many verticals. One example of this is in the recently opened Spartanburg, South Carolina-based FR8yard, a vibrant beer garden with authentic German beer tables with benches. To enhance patrons’ experience, a 10′ x 16′, 6.667mm pitch modular SMD LED display was installed and can be seen from a 160° horizontal viewing angle, important for this venue. And, because much of the programming will be sporting events, the display’s 60fps and fast refresh rate provide smooth video playback, as if the viewers were watching on a stadium’s jumbotron. The exterior display has weatherproof features, including waterproof modules that are certified IP65/IP54, making it resistant to harsh external elements like rain, wind, dust, and heat.

Heat Dissipation Advances

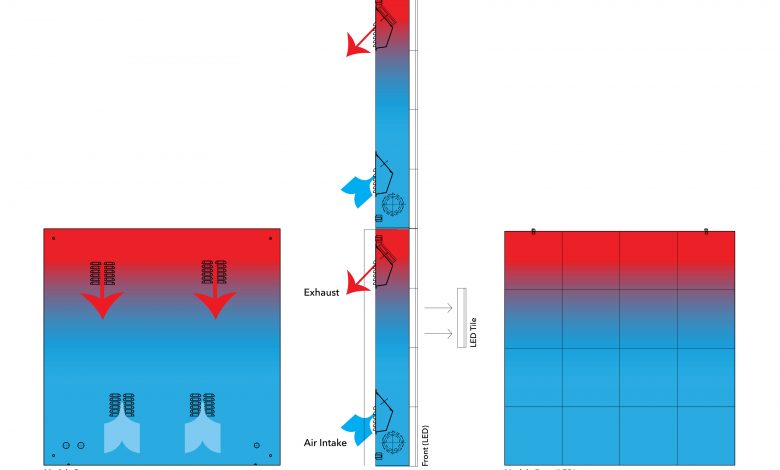

For billboards and large-scale spectacular displays, air flow management is critical to achieve a long-lasting display and reduced energy costs generate a faster ROI. Proper ventilation is key for the display to be successful.

One advantage of modular cabinets is that each cabinet is smaller and has an individual rear ventilation system, allowing for faster cooling. Therefore, massive fans aren’t needed to circulate air through a large cabinet cavity. Modules that are warmer can exhaust and, because other cabinets are running cooler, power is reduced and fans only activate to push out excess air. Heat sensors and on-board diagnostic utilities help regulate temperatures so the display works more efficiently. Additionally, there is less noise compared to larger front-ventilation cabinet designs.

Many companies are moving to new, high-efficiency fan-less power supplies, with some achieving over 88 percent efficiency. The power supply is typically the most common point of LED display failure. In outdated LED displays, clogged or broken fans cause the supply to overheat and burn up. By removing the fans and increasing efficiency there is a reduction in overall heat from the supplies. The rest of the heat is then dissipated by the aluminum cabinet it is housed on creating a large heat sink in the rear where airflow quickly cools it.

Importance of Weatherproofing

LED displays and billboards can be installed in a variety of all-weather environments and are engineered to withstand pounding rain, blowing dust, beating sun, strong winds and frigid snow. Because electronics generate heat, and expand and contract in their natural environments, they need to “breathe.” However, while it’s imperative to protect against the elements, it is difficult to fully seal something because of the need to exhaust excess heat.

The International Electrotechnical Commission (IEC) sets the Ingress Protection (Ip) rating, which determines the sealing effectiveness of electronic equipment or electronic enclosure. It is useful as a standard measurement of electronic equipment’s resistance against external harmful elements and is the most important variable in distinguishing outdoor rated displays/billboards/modules versus indoor ones. Older LED displays contain the IP65 rating, which means the equipment is virtually impenetrable by any of nature’s elements. However, companies are now producing modules with an IP67 rating for the tile (module) and an IP65 rating for the cabinet. To achieve the tiles’ IP67 rating, they are fully sealed with a thermal conductive polymer applied to the rear, which provides additional weatherproofing and allows for heat dissipation.

Maintenance, Monitoring, and Security

Billboards and spectacular displays also require attention to maintenance, monitoring and security. For example, advances in cabinet engineering have greatly improved maintenance, especially with front and rear service options. Additionally, some manufacturers have eliminated multi-pin (traditional 30-40 pin connectors) ribbon cables, which means faster tile changes, fewer damaged cables, and tighter connections. Fewer cables provides a reduction in display weight and clutter, making it faster to find critical components, and less areas for heat to get trapped inside.

A few companies have moved to advanced, single-point 5-6 pin power and data connecters using low-voltage differential signaling (LVDS). The elimination of ribbon cables and use of LVDS significantly reduces EMI (electromagnetic interference) emission, which can cause disruption to surrounding signals, making a large billboard display or spectacular a target for FCC fines or to be shutdown.

Other industry advancements include a reduction in daisy chained outages-when one tile is out but not the display’s entire row or section as well as redundant data and power that helps lessen signal interruptions and outages. We are also seeing smarter LED tiles with built-in CPUs to store more information, color calibration and runtime data and other critical material to help keep the display looking as uniform, bright, and vibrant as possible. This information can be accessed through a diagnostic utility from a remote location, which makes site adjustments easier, calibration data more accurate, and provides an odometer to more precisely gauge the display’s runtime and life expectancy.

High-Tech Diagnostics

For security, maintenance, proof of performance and environmental observations, 24/7 visual monitoring occurs with front-facing cameras. Recently introduced to the market are diagnostic utilities in a range of technological sophistication. For example, some displays use a base level while others have a more advanced system that even includes the pixel for high-profile, high-resolution installations.

Multi-layered diagnostics allows remote access for service teams to conduct system checks, quickly identify problems and dispatch parts or repair teams to the site faster and with greater accuracy, reducing downtime and service trips.

Cyber security is an issue for high-profile billboards and spectacular displays, particularly in larger cities. To combat this, direct fiber optic network infrastructure is housed behind heavy firewalls, which also allow larger data signals like live video to display without bandwidth issues. Billboards located in remote areas require different communication options such as cellular modems maintained by the cable carrier with each location having a unique, secure IP address. Additional firewalls and password protection options can be added. Using this communication technology makes installation and setup easier, eliminates less secure, wireless communication options, and simplifies remote-location display installation. Manufacturers are opening the hardware to allow billboard companies to use their proven and secure third-party digital signage players, making it easier for them to add to their existing network of displays.

Conclusion

Today, more than 7,300 digital billboards operate nationwide. With high-brightness, high-resolution LEDS, the conventional billboard has been transformed into the perfect high-tech electronic outdoor display medium. The industry is fully engaged and developing ever-advanced modular solutions to meet the customers’ changing needs. While we’re seeing these implemented in high-profile billboards and displays, engineering is moving toward making them available in smaller applications for greater adoption of the technology.