Laser Engraver Maintenance

Tips for keeping your laser engraver running like new

Regardless of whether you use a CO2 or fiber laser, both systems require maintenance to stay at peak operating performance.

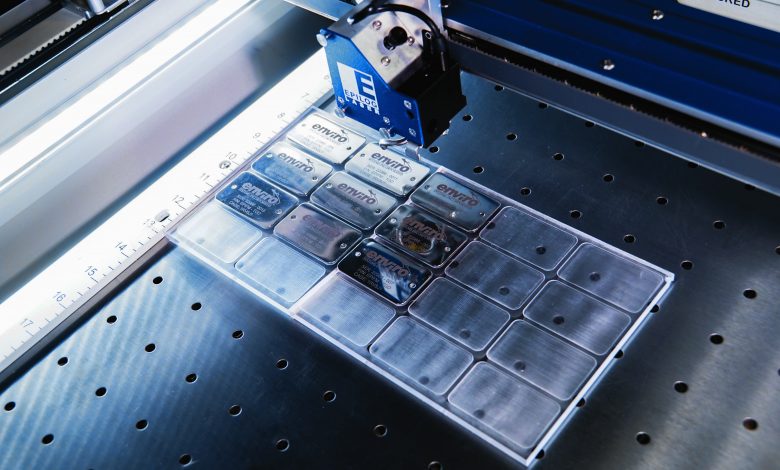

Industry veteran Josh Stephens says the maintenance really depends on how heavily the machine is being used and what it is processing.

“If you are running a lot of wood, wood throws off more smoke so you are going to have a more frequent cleaning cycle on the machine to help maintain it,” he says. “The biggest thing with laser machines is to keep them clean.”

It is important to remove dust and debris from inside the machine and from the mechanical components because if you leave it in there it will cause friction which will wear out the laser head, bearings and belts over time, he says. It is important to keep the laser head clean. Stephens recommends that shops check the optics on their laser head daily.

“It is good practice to make sure it doesn’t damage the optics. The lens will crack if it gets hot or [debris] will burn onto it and you can’t clean it off,” he says.

Todd Tugwell, global service director at Universal Laser Systems in Scottsdale, Arizona, says that while processing material, either by cutting, marking or engraving, “you are going to get the burn-off effect. If you are engraving a bar code on some aluminum, you are going to have very little burn off. You don’t have to clean the optics that often. If you are doing something like foam or rubber stamps or leather that puts off a tremendous amount of smoke and gas, it can cloud the optics quite quickly so you want to clean those quite often.”

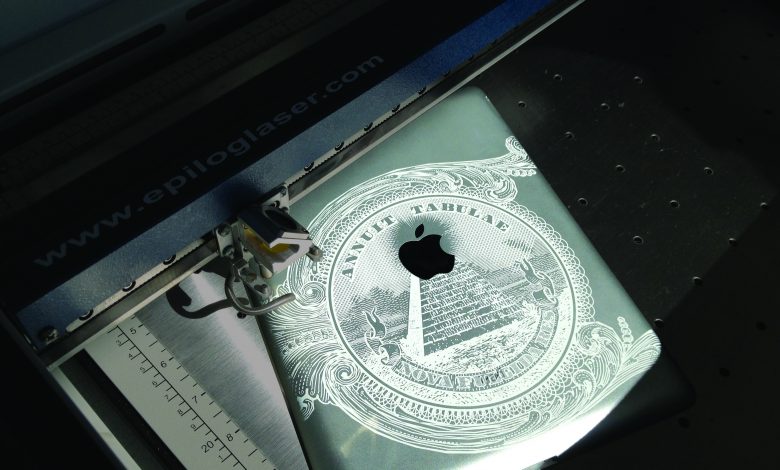

Mike Dean, director of sales and marketing for Epilog Laser in Golden, Colorado, says that it is simple to keep the optics clean. Use a soft cloth and either water or a citrus-based cleaner, like Go Green, to keep the debris off the lens. Epilog includes an optics cleaning kit with all of its engravers. It includes optical paper and lens solution. You just dab the lens solution onto the optics or mirrors and wipe it off with the lens paper or a cotton swab.

“That’s the biggest part of maintenance and for some reason it seems difficult for people to keep their machines clean. Usually they let the smoke or residue build up and start gunking everything up. If you spend five minutes a week cleaning your machine it will last a lot longer,” Dean says.

If you don’t clean debris from your machine, it will destroy the bearings. He says that Epilog machines come with a warning. Don’t try to engrave on PVC. If you do, it voids your warranty.

“The residue eats the machine from the inside out. It can be nasty,” he says.

On some lasers, it may be required to replace belts and bearings on a regular basis. On other lasers, this isn’t a common occurrence because everything is sealed off so it will last longer.

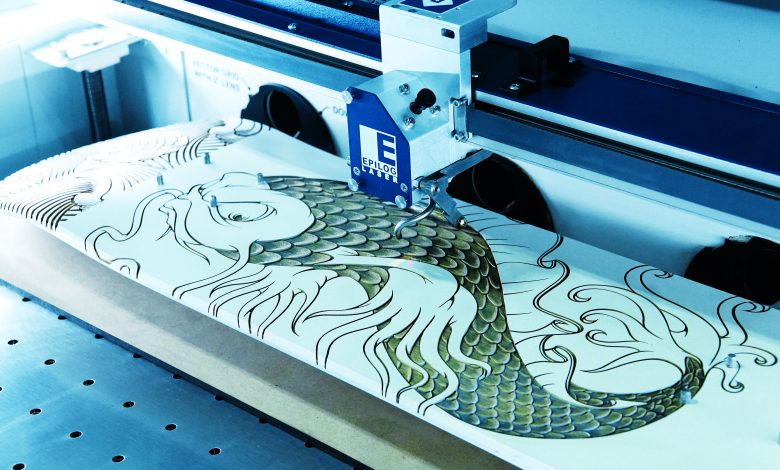

The belts are what move the carriage on the arm. The carriage, which sits on the X-axis, has optics to direct the laser beam onto the surface of whatever you are engraving. It moves horizontally. The Y-axis moves back and forth. The Z-axis dictates how high the carriage moves up and down.

You want to get the laser to its optimal focal point, Tugwell says. “If you draw an upside-down triangle, that tip of the V is your focal point. You want to have that match right onto your surface. That will get you the best results,” he says. Any damage or debris on the optics will skew the laser beam causing poor-quality engraving or marking.

Alignment of the laser beam and leveling of the laser engraver itself are also very important. Before you start using your laser engraver, it is important to not only level the device to the floors or structure it is located on, but also the table itself that supports the material you are processing. The reason that is important is that you want the focal point of the laser beam to be precise.

“If the system is not level and your beam is moving across the X-axis, back and forth, if it is not level it will go out of focus at one point of field or the other. If it is out of focus, it is going to provide poor results,” says Tugwell.

The alignment is also key. As the laser beam comes out of the laser it reflects off mirrors, focusing the optics through the carriage and down to the surface. If the mirrors are out of alignment, by the time the beam “gets to the final output in the carriage to the surface, that dot in the middle of the circle is off to the upper right or lower left. If it is off, there is a cone-a little cylinder on the bottom of our laser-it will clip the edge of that cone and you lose some of the strength and focus and power of the beam and it will give you very poor results,” Tugwell says.

Another thing that gets neglected by laser owners is the exhaust system. It is crucial that laser owners remove all the debris and fumes they are generating from the extraction unit at least once a year, more if the machine is experiencing heavy use. The few times laser engravers have caught on fire were because of operators neglecting their machine maintenance, Stephens says.

“If you don’t maintain the exhaust system and keep it running well, if it gets bogged down, it won’t be removing debris and fumes and could cause materials to ignite,” he says.

If your machine has an external exhaust that vents to the outside, you will want to inspect the exhaust blower and all of your connections semi-annually, he adds. If your machine uses a filtration system, it is important to replace the filters when it is time. That depends on how used up the filters are. In some cases, you can clean the filters and get some extra life out of them. Some owners use a pressure washer to clean them off.

Filters will need changing more often depending on the substrate being engraved. Wood and plastics discharge more dust and debris than fabric, for instance.

“After you operate a few months you can get a feel for when you need to replace the filters based on work flow,” Stephens says.

The CO2 must be replenished after three to five years, he says, but fiber lasers use glass silica optic fiber that has crystals. The average fiber laser engraver will last between 80,000 and 100,000 hours of operation.

“They can literally run 24/7 for eight years,” he adds.

Fiber lasers are used to mark metal, while CO2 lasers are used on organic materials like wood, paper, plastic, glass, foam and fabric.

“Your preventive maintenance varies greatly depending on the materials you are processing,” says Tugwell. “Think about it like a copier. After 10,000 copies, you need to rotate the drum and clean the components. With lasers, you need to clean your optics, examine belts and bearings.”

All CO2 lasers traditionally operate the same, he says, they just use different wavelengths.

You will need to recharge the CO2 tube after about five years, Dean says. The actual tube will last 10 to 15 years.

The laser tubes don’t require much in the way of maintenance, he says. Usually, the owner will tell the manufacturer they need a new laser tube. Epilog will send it to them and they will send the old one back to be recharged. Others just keep a replacement laser tube in stock so that they don’t miss any work time when the CO2 goes out.

Commercial customers run their laser engravers more than eight hours a day, seven days a week.

“I always tell people the reason they are so durable is we are moving light around. The laser beam is a light beam so you’re not doing a lot of mechanical work like rotary engravers. They are always digging into stuff, plastic or metal. But we’re just moving light across the surface so the amount of stress that gets put on the machine is really pretty minimal. That’s one of the reasons they tend to last so long,” Deans adds.