At 37, Joey Gerhart has already been bending neon for almost 20 years. That’s in a trade that some people in the sign business might think-like hand lettering-is no longer sustainable or relevant. But Gerhart is part of a community of tube benders scattered around the U.S. who know better…

Gerhart started this tube-bending career path at the Birmingham, Alabama-based wholesaler, Sign Builders Inc. in 1999, right out of high school. It was about the same time that LEDs were first introduced as a light source for signs, but most channel letters and cabinet signs were still being lit with either neon or fluorescent lamps.

It was supposed to just be a summer job to appease his father who insisted, since he decided not to join the Navy, “You have to find a job until you figure out what you’re going to do.”

It happened that a friend’s brother, who worked at SBI, said they were always hiring. So Gerhart and his friend got themselves hired on. “They threw me into the neon shop as a helper,” he remembers.

“That was back when they had four or five benders. They taught me how to pump the neon and eventually I learned how to bend.”

Gerhart says he learned the basics of neon tube bending on the job while working at Sign Builders, but a breakthrough came when he met Morgan Crook, who at the time was the technical support engineer at Transco, and who would occasionally visit the shop. (Crook at the time also penned “The Neon Jungle” column for Sign Business magazine, the predecessor to Sign & Digital Graphics.)

“My boss told me, ‘This guy knows what he’s talking about. If you want to learn, ask him questions.’ So I asked every question I could think of that my boss could never answer.” After so many questions, Crook suggested he get a copy of The Neon Engineer’s Handbook, by Crook and Jacob Fishman. “I had to unlearn a few things, but the book explained how to do them correctly and showed how and why the way we were doing it caused problems.”

The sign lighting paradigm shifted when LEDs became bright enough, abundant enough, reliable enough and cheap enough to be installed easily into channel letters and cabinet signs.

It was easy enough to see the change in store for the neon trade.

“When LEDs first hit, we laughed about them because they were so expensive,” Gerhart remembers, “and they weren’t very bright compared to neon. But then they just started getting brighter and cheaper.”

That’s when the neon departments of sign companies started changing. Big wholesalers, as well as small Mom ‘n Pops closed up shop. And the fires, the racks of glass, the patterns, the neon lights-and the tube benders-simply moved on. Gerhart was the last tube bender to work at SBI, until it too closed its neon shop in 2014 and he also moved on.

Moved On, but Not Out

It was inevitable that SBI would eventually close its neon shop, so when the time came, Gerhart put his own shop together with equipment pieced together from a couple of sign shops that had also closed their neon departments.

He started an independent shop and quickly confirmed neon is still in demand: “When I left SBI, all the sign companies got the word out and they were calling me, wanting to know when am I going to be up and running. So I was busy from the get-go,” he says. And he’s been busy all along and ever since and the work he does is as varied as neon lights can be.

An upside to the diminished neon industry is that there are fewer people around who still know how to “make neon,” so the skills he’s been refining are still in high demand. A lot of the bread-and-butter work comes to him through sign companies that need neon made for new open channel letters and similar exposed neon projects, or they need an existing sign repaired.

Most people don’t realize neon is hand made, thinking it’s machine-made in a factory somewhere. And being hand-made, every piece, no matter how meticulously a person follows the pattern, has a uniqueness to it that only comes from being hand made. This uniqueness is valuable to many discriminating clients who want that hand-made quality in a product.

Which leads to another facet of Gerhart’s neon business: selling neon signs through Etsy.com, something made possible (and practical) only relatively recently through the miracles of FedEx, UPS and the internet. After only a few months, he says it’s surprising how much interest there is. So far, most popular are neon “OPEN” signs that are anything but ordinary, but there’s also a lot of interest in any kind of custom neon sign-or art.

The Value of Pi

Gerhart’s business is a classical one-man show and an example of how working at something for long enough brings rewards. And how there’s plenty of room for independent, artistic entrepreneurial individuals to compete in the sign industry and thrive.

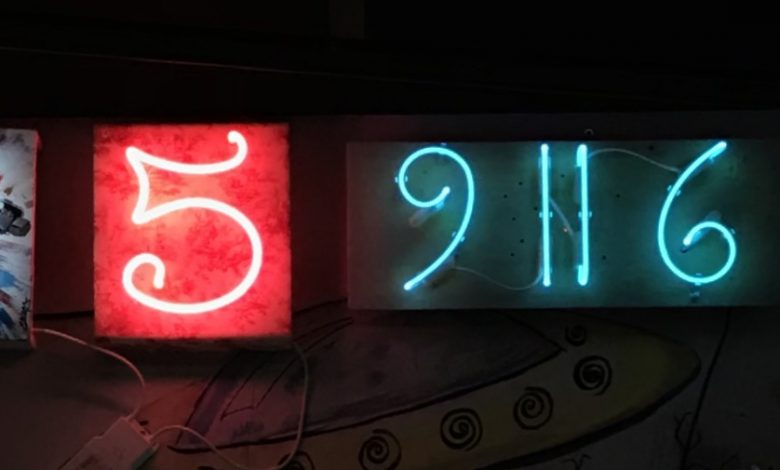

When not working on a job for a client or playing bass with some musician friends, Gerhart adds to his neon colors display. For decades, the unofficial “standard” for showing clients available colors and tube sizes in neon shops was a bank of different colored straight tubes for samples.

Boring, thought Gerhart, and he thought up an idea while eating a piece of cherry pie: pi.

That is, three-point-one-four-one-five-nine-two-six, et cetera, et cetera, et cetera. So far, and with contributions from a few other tube benders he stays in touch with, the display now extends to 11 digits and is growing.

Gerhart’s future plans are to keep adding to itÂ-and to keep getting better: “to never stop learning new tricks from other people; working on every kind of bend and weld; listening to the older fellas’ advice on bending neon and trying to make it look as good as possible.”

He says he runs across a lot of people who talk about wanting to learn to bend neon, who think it would be really cool. “But I guess once they realize how much goes into it, how much you have to remember and how long it’s going to take before you’re good at it-they lose interest. I would really love to find someone who wants to learn like I wanted to learn when I got thrown into a neon shop. It was exciting to me.”

Gerhart’s future plans might also include moving to a larger shop with Signage, the sign shop next door that he collaborates with often and who he rents his shop space from. Signage does sign installations and service work with its bucket truck, and provides design and digital printing services.

So his future neon shop might be in a different place, but the fires are sure to burn just as hot-and plenty of “Pi” will be served up for those hungry for the real thing…