Custom window, wall, and floor graphics can heighten a business as well as a product’s appearance to potential customers. Graphics can share news of promotions, sales, store hours, and new inventory, as well as making a business logo pop or creating a huge sign for an ad campaign or sporting event. For example, custom window decals are a crucial driving force for attracting new customers into retail or storefront business.

There are a host of options to get your client’s message across, from solid to clear, one-sided or two-sided, and see-through graphics with either permanent or reusable adhesives. Each of these applications for windows, walls, and floors requires different types of materials for the projects they are going to be used on and for the surfaces to which they will be affixed.

Jay Kroll, product manager for cut, transit, and wall solutions at General Formulations, said that from a surface level, it’s easy to look at the world of window, wall, and floor graphics and think they are all just essentially the same sticker in different sizes and stuck on different surfaces.

“As we look closer, we can see that each one carries its own specific features and requirements for a successful install. Whether it’s a window film that has the clarity or block-out feature we need, the wall graphic that overcomes the challenges of paints and surface types, or the floor graphic with a laminate designed for safety and durability, they all have unique characteristics that need to be understood and embraced for successful, repeatable, and profitable jobs,” he said.

New developments in technology

Kroll explained that as printer technology advances and white ink sets become more popular, shops have more options on projects. “One trend that seems to be growing is single-pass push/pull graphics with five-layer print on a clear removable film. For projects like these, an optically clear vinyl pairs beautifully with UV, UV gel, or latex ink sets to bring the concept to life.”

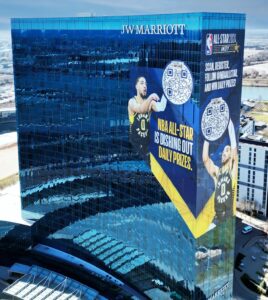

Kroll added that window perf applications also continue to grow beyond just simple storefront displays and transit windows to large building installations. “A glass facade wrapped in window perf can provide the same impact as a wall wrap on the exterior of a building, but with a much easier application surface than brick or block. Working with a 70/30 or 80/20 perf will still allow plenty of light to enter the space and provide good visibility out, all while creating a visually solid image for the audience.”

Kroll said that from a business and workflow standpoint, the best films are the ones that work reliably, are readily available, facilitate your creativity, and make you the most money.

Kroll explained that office decor is trending toward creating a sense of space with intentional environments, and that is often done with a mixture of window and wall materials. “One easy way is by mixing privacy with design, incorporating films that mimic the look of etched glass.”

Amanda Smith, marketing and communications manager at Mactac Graphics & Signage Solutions, said that there are several differences between window, wall, and floor graphics. “The first that comes to mind is the adhesive. It is important to use different kinds of adhesives to get the best results when applying them to concrete, glass, and drywall. Another point is the application in dry spaces or wet conditions like floor graphics. Keep in mind that the difference is the film used for the applications. For example, windows and privacy films differ from what is needed for walls, like gloss versus matte white and the texture and anti-slip needs of floor wear-and-tear applications.”

Smith pointed out that when it comes to window graphics, there has been an increased awareness in recent years of how PVC affects the environment, which has led many consumers to seek out more eco-friendly alternatives. “I think the demand for PVC-free media and green alternatives is likely to continue growing as more people become aware of the environmental impact of items and seek out alternatives.”

She noted that working with PVC-free window media options for print service providers can have several benefits. “First, it shows they are taking steps to be environmentally responsible and cater to the growing demand for eco-friendly materials. This can help attract and retain clients who prioritize sustainability. Additionally, green alternative media may offer better durability, resistance to fading, and improved print quality compared to PVC-based materials. This can lead to higher customer satisfaction and repeat business,” she said. “Finally, using PVC-free media may help the print service provider comply with any regulations or incentives that encourage the use of eco-friendly materials. Overall, working with PVC-free window media options can benefit both the print service provider and their clientele.”

Molly Waters, senior technical specialist at Avery Dennison Graphics Solutions, said as film technology continues to evolve, the differences aren’t necessarily about the products but rather are more about the applications and the nuance of surfaces required for adhesion.

“These days for wall applications, we typically default to films using a permanent adhesive,” said Waters. “This is because most of today’s wall paints are low-VOC, which makes it difficult for adhesives to stick to them. Sometimes shops have had to go to a high-tack adhesive to ensure adhesion to walls with low-VOC paint.”

For example, she said the company recently had their textured wall films tested to the UL410 slip resistance standard (used for floor films), and they passed. “Now these films can be used for walls and short-term floor graphics,” Waters said.

She explained for windows, optical clarity and removability usually drive material choice. “We have printable white films that go on easily and are also relatively easy to remove, which makes them a great choice for short- to medium-term promotional signage.”

Waters said that the biggest trend they are seeing in window film is requests for more decorative looks. “Texture and patterned glass designs, like the trendy art deco-inspired fluted glass finish, are in high demand. Decorative films give shops the ability to expand their film and installation services to offer options for both commercial and residential applications. Film and adhesive technology are evolving creatively in today’s marketplace for sign shops to grow their service offerings. “Window films that specialize in a certain function — such as deterring bird strikes on high-rise buildings — represent another example.”

Window, wall & floor graphics applications

Mactac’s Smith points out that for indoor/outdoor window displays, she has seen many large installations in college and university settings. “This market has ample window space to promote the schools’ upcoming events and students while being both long- and short-term applications. Low-tack adhesives can make short-term application installs go easily up and down quickly.”

When the University of Chicago contacted local shop ER2 Image Group about creatively promoting a traveling art exhibition within the space, sign shop ER2 offered some great creative options. With a motto to make branding bigger, the full-service grand format printing company — which specializes in the design, creation, and installation of large-scale graphics projects — designed and installed graphics across the glass dome to reflect the featured artist’s work.

A key priority of the project was to maintain the sunlight coming through the windows yet soften it with necessary illumination. To achieve this, ER2 used a printing technique on its Vutek GS3250LxPro printer that encompassed UV-curable ink and a three-layer print process. “This printing technique is best for back-lighting applications, so it worked perfectly for keeping the printed image strong while allowing light to pass through,” said ER2 Vice President and Partner Mark Schellerer. “Also, we decided to go with Mactac’s polyester Crystal Cling film because it is optically clear and can be butt-seamed to ensure the passage of light while eliminating possible shrinkage or expansion.”

The wet installation was completed in roughly five days by four installers who primarily worked in the evenings when there was lighter library foot traffic. The team used a lift with an extension arm to access hard-to-reach installation areas and maneuver around the limited floor space.

Smith said for office decor, window films designed for privacy and finishing purposes offer several benefits apart from privacy and aesthetics. “It can help reduce the amount of UV rays entering a space, which can help prevent fading of furniture, floors, and other interior elements. They can also offer energy-saving benefits by reducing the amount of heat entering a space during summer months and retaining heat during winter months. Additionally, some window films can provide safety benefits by strengthening the glass, helping to prevent breakage and shattering during natural disasters or break-in attempts. Overall, window films designed for privacy and finishing purposes are a cost-effective solution offering several benefits to both residential and commercial settings.”

Smith reported that when multinational technology company Cognizant sought a unique way to incorporate company branding and employee privacy, the team turned to local graphic design and signage company, Mixed Media Concepts.

Specializing in wide-format printing and architectural signage, Mixed Media Concepts recommended a combination of printed and unprinted window graphics that could be applied to the glass surfaces. Nick Basile, Mixed Media’s owner, suggested IMAGin B-free frosted window film to create a consistent finish for both printed and unprinted graphics. The product worked great and in just one week, three installers put up 4,000 square feet of material. They installed printed and nonprinted material on both the first and second surfaces. The printed material was printed using an HP Latex 360 printer.

“We transfer-taped all frosted film for the project, which made it go down like a dream. It saved time being able to install dry, cutting our installation time in half,” Basile said. “The customer was very particular about the project and was ecstatic about the quality of the material and installation.”

Smith said another recent project involved the Streetsboro Fire Department in Ohio, which wanted to honor the lifesaving work of its firefighters by incorporating an inspiring display of artwork within its fire station. An exposed interior brick wall presented the perfect canvas. Seeking a mural with a paint-like appearance without using paint, the department turned to Central Graphics, a print, production, and graphics installation shop in Akron, Ohio.

Central Graphics led the department straight to Mactac Roughrap RR100 wall wrapping film. They knew the material would sink into the wall and offer a painted look and better longevity and protection than paint with the addition of the Mactac Rayzor overlaminate. Artist Jessica Lofthus was commissioned to design the art for the 11‘ X 12‘ wall graphic, and Central Graphics printed it using a large-format Epson printer.

Looking ahead

Kroll added that advancements in film technology, especially cast but also with calendared films, have driven the industry to develop materials with characteristics like longer outdoor durability or greater conformability. When paired with adhesives that can be applied on more challenging substrates or at a wider range of temperatures, these innovations help to allow sign shops to be more creative knowing that the materials they use will stand up to the rigors of their creativity.

“These developments are also being made with sustainability in mind, through improved chemistry and manufacturing practices, encouraging responsible growth as new materials and paths are pursued,” he concluded.