A key factor to take into consideration when purchasing tools for your shop are your goals. Ask yourself and your team:

- How long do you plan on being in business?

- What type of space do you currently have? Is there room to grow if you choose?

- Can you hire enough staff if needed, or are you a one-person show?

- What is your power source and how much can it handle?

- What types of products do you want to customize?

Every company is unique and offers something different to their customer base, and I hope this article allows you to see your full potential. If you choose to grow your company or simply maintain, the best tools make the workload easier.

It’s well after the COVID-19 pandemic and it seems everyone is still having issues finding help. Those who aren’t scrambling for employees researched and invested beforehand to get ahead of the curve during the pandemic. They worked to find processes that truly expanded in-house product customization and made it easy for teams to teach new hires who haven’t done customization work before.

First, let me list which processes I suggest you look into investing in and why, since I have personally invested in and built out pricing and production for each — while working with my team in the process.

- Direct-to-film (DTF) printing

- Laser engraving

- UV printing

- Embroidery

- Vinyl graphics

Direct to film

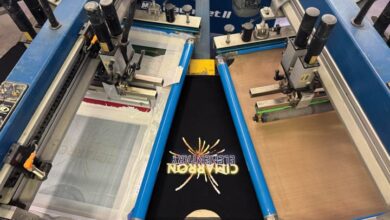

Why did I list DTF first although it is still such a new process for our industry? I have been in this industry for 21 years and I have never seen a process so powerful out of the gate. We ordered our machine from ColDesi, which was the DTF 24H4, at the end of 2023 and had it installed and up and running by the end of January of 2024. We slowly rolled it out to our customers to educate them on the process of the full-color print along with the quality they get for the money. We purchased the largest printer they had, and then over a three-month period, we purchased four Hotronix Air Fushion heat presses to keep up with the demand. All of this equipment takes up less than 250 square feet of space to pack a production output punch! This year we will produce around $750,000 with the printer.

Laser engraving

We have only been doing laser engraving for three years. We started off with our 3D laser to be able to pound out several units of drinkware per hour. It also allows us to laser engrave on to wood and more! Depending on the size of the design, we can hit 100+ pieces per hour with ease.

Two months later, we invested into a 2D laser which allows us to laser engrave leatherette patches and anodized metal — like pens, awards, and more. We can laser a pen in under three seconds and easily produce around 60-plus patches an hour.

The last laser we invested in was our UV laser. What a game changer. We can now laser engrave glassware and crystal in-house. We easily get 50 to 60 glasses done per hour. And all three of these machines only take up 100 square feet of space.

UV printing should really be second place as you can print full-color onto just about anything — depending on the machine you have. I invested in the LOGOJET UVx90i which has a print area of 24“ X 36“ and can fit anything up to 6“ under the print heads to print full color onto the surface. The other game changer is creating UV transfers to hand-apply certain items to ramp up production even faster. Our main goal was printing normal yard signs and 24“ X 36“ yard signs to reduce our cost in vinyl graphics and labor, ramping production up faster. While this machine prints yard signs, our team can be doing something else and doubling our output. This machine takes up less than 50 square feet of space and packs a major punch!

Embroidery

Embroidery is the second process our company started with from our home 19 years ago. It is a very expensive process to get into, but it is worth it in the end. We started with two single heads in our home with a 14‘ X 14‘ room, where I also designed and did sublimation. Now, we have four single heads, a two-head, and a six-head machine. This all fits in a room that is only 650 square feet and produces around $900,000 in production. And we still haven’t maxed out what we can produce. The other fun fact is average loans on these machines are five years and the average machine, if taken care of, can last more than 20 years. So, while the machine is not cheap, your ROI is huge because you don’t have equipment payments for 15 years. Our total investment with software is around $225,000 and all of the equipment, except for two new single heads, has been paid off for years. No matter what, you will always want a minimum of one single head for sew outs, names, numbers, etc. to ramp production up. Always create production options.

Vinyl graphics

Vinyl graphics are another old school technology that can make your shop well rounded. We have a 54“ and a 64“ vinyl printer that both print and die cut if needed. We also have a 60“ plotter and two laminators. At one point, we had all of them in one space and it took up around 200 square feet. I have to be honest about this process — it is a moneymaker, but I never have really pushed it the way we could be due to how fast we naturally grow. We produce around $300,000 a year in vinyl graphics. We use this process both for our in-house needs and to make us well-rounded for all customer needs. You can make serious margins with this process.

So, no matter if you are looking to simply offer one process or add to what your company offers, it pays to become well-rounded and less dependent on anyone else doing work for you. These processes and equipment recommendations will allow you to offer more and do more work with the same amount of staff members, making it easier to pay the equipment off, keep your clients coming through your doors, and investing more into your staff. This essential list can take your company and team to a whole new level, and our company is proof that it works!