In the garment decoration industry, the quest for efficiency, quality, and innovation never ends. Direct-to-film (DTF) printing, a relatively new entrant in the textile printing arena, has quickly captured the attention of the garment decoration industry. But as with any emerging technology, the question arises: Is DTF printing the right fit for your garment decoration needs?

What is DTF printing?

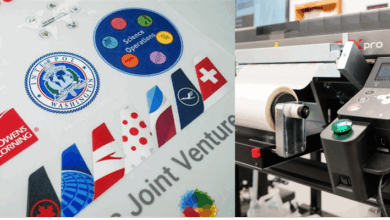

DTF printing is a process that involves inkjet printing designs onto a special type of film, coating the printed design with an adhesive, curing it with heat, and then pressing the transfer onto fabric using a heat press. Unlike direct-to-garment (DTG) printing, which requires pretreated, mainly organic-based fabrics, DTF allows for more versatility by permitting transfers to be applied onto a wide array of textiles, regardless of fiber content, shape, or color. This ability to decorate a vast selection of materials positions DTF as a potentially revolutionary method in the garment decoration industry.

Key advantages of DTF printing

- Versatility: DTF’s biggest advantage is its versatility. Users can apply designs to cotton, polyester, and blends without the need for specific pretreatments for different fabric types. Also, due to DTF‘s adhesive technology, it is versatile enough to be used on a variety of chemically-treated fabrics, making it an excellent choice for decorating sports uniforms and stain-resistant workwear. Given its flexibility, DTF is ideal for applying designs to shoes, caps, bags, and other 3D objects. Its lower temperature application enables the decoration of certain temperature-sensitive fabrics without damage and greatly diminishes press lines or heat press boxing.

- Color vibrancy and quality: DTF printing is known for producing photo-quality prints with vibrant colors and exceptional quality, resulting in outputs that are not only visually stunning but also highly durable and resistant to repeated washing. This remarkable durability and color vibrancy make DTF printing an ideal choice for high-end fashion items that demand a premium look and feel, as well as for everyday wear that requires resilience to frequent laundering. Its advanced digital technology significantly enhances its capability to match colors with exceptional accuracy, unlike many other decoration methods.

- Cost efficiency: When compared to traditional printing methods, DTF printing requires lower setup costs, and lends itself to “one-off” prints making it ideal for small to medium-sized runs. This can significantly reduce inventory costs for print-on-demand apparel printers. Since there are no pre-production expenses as seen in screen printing or DTG printing, an automated DTF printer could achieve substantial cost savings over these printing methods in some situations.

- Environmental impact: With its no water consumption and minimal waste production, DTF printing presents a more environmentally friendly option compared to some traditional textile printing methods. As it secures an increased market share of decorated products, new advancements are being pursued to make the process increasingly more sustainable.

Considerations for garment printers

While DTF printing offers many benefits, there are several factors garment decorators should consider:

- Initial investment: The upfront cost for DTF printing equipment and supplies can be significant, though it is often quickly recouped due to the technology’s efficiency and versatility. A number of DTG printers are capable of producing DTF transfers, meaning the additional cost for equipment could be minimal if you already possess a hybrid DTG/DTF printer.

- Technical skill: Successfully implementing DTF printing not only demands a technical understanding of the process and the equipment involved but also necessitates that printers may need to consider investing in comprehensive training programs for their employees. This is crucial to ensure that all personnel are fully equipped with the knowledge and skills required to effectively manage and safely operate DTF printing technology, thereby optimizing the quality of the finished product.

- Production speed: For businesses or projects with very high-volume printing needs, the speed of DTF printing might not yet match that of some traditional printing techniques, such as screen printing or automated DTG. However, it’s important to note that progress in the field of DTF printing technology is ongoing, with advancements being made regularly. These improvements are aimed at increasing the speed and efficiency of DTF printing to better meet the needs of high-volume users in the near future.

- Safety considerations: If not managed with strict adherence to safety protocols, the powdering and curing processes in manufacturing DTF transfers could present significant risks to health and safety. To reduce these risks, it’s crucial that production staff are provided with the proper personal protective equipment (PPE), such as gloves, goggles, and respirators. Furthermore, providing comprehensive training that covers the proper handling of materials and equipment, emergency procedures, and the correct use of PPE is crucial for ensuring a clean and safe working environment.

- Outsourcing: Many decorators prefer to avoid the equipment cost and hassles associated with maintaining equipment and training staff. Fortunately, there are reputable firms that excel in producing custom DTF transfers. These companies, known for their expertise and quality, offer a simple yet effective process for acquiring these transfers. By sending them your print file, whether it’s a detailed graphic or a bold logo, these specialists will create the transfers using their advanced DTF equipment. Once produced, they carefully package and send the transfers to you, ready for pressing onto your choice of apparel or merchandise. This streamlined process ensures that you receive high-quality transfers tailored to your specific needs, eliminating the complexities of in-house production. This service presents a fantastic opportunity for beginners in DTF printing, as they only need a heat press to start offering DTF embellished garments. With minimal equipment costs and no need for transfer production, it presents an accessible and attractive option for those interested in offering DTF-decorated garments.

Is DTF printing right for you?

DTF printing represents an exciting opportunity for garment decorators looking to enhance their product offerings and adapt to changing market demands. Businesses that benefit most from DTF typically have diverse product lines that span different fabric types and smaller order quantities.

If your operation values flexibility, quality, and sustainability, DTF printing could be a game-changer. However, it’s essential to weigh the initial investment against the potential benefits carefully. Consider starting small, perhaps by outsourcing the transfer production before purchasing equipment. Many decorators begin by adding DTF printing as an additional printing method to their current operations and gradually increase its use after assessing its effects on product quality, production speed, and overall profitability.

As the apparel manufacturing industry continues to evolve, DTF printing stands as a significant innovation. Its potential to deliver high-quality, efficient, and versatile garment decoration makes it an attractive option for many printers. However, like any technology, it’s not a one-size-fits-all solution. Assessing your current operations, market demands, investment, and future business goals will help you determine if DTF printing is indeed the right fit for your business.