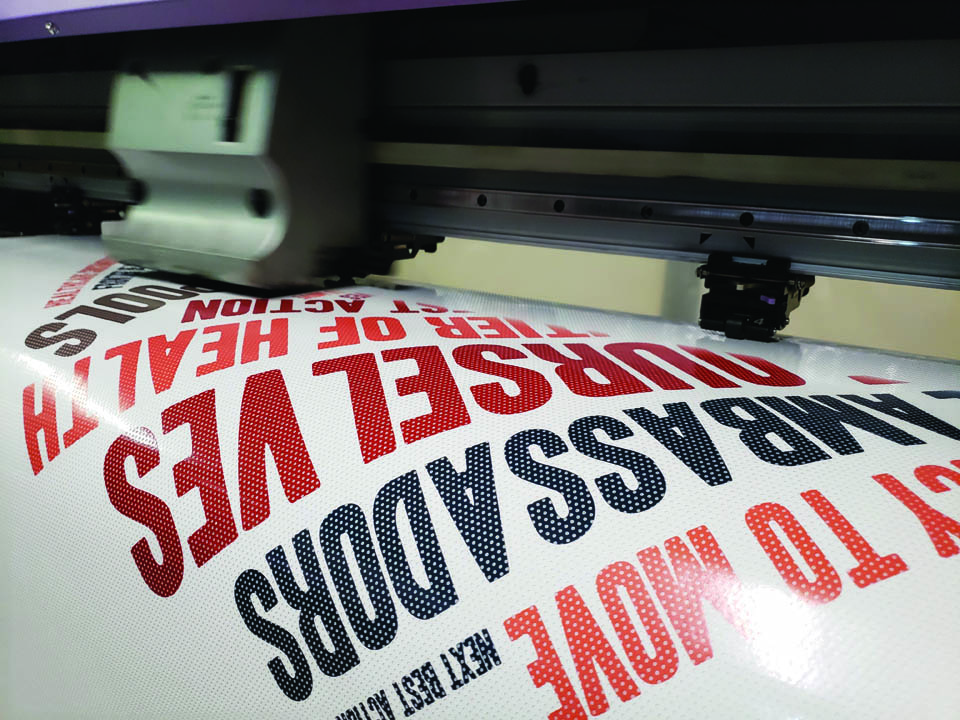

As trade show season approaches, it is important to examine the benefits of wide-format printing when it comes to producing trade show booths, banners, and graphics. Wide-format printers are versatile because they can print on many different types of substrates, but material costs aren’t the only things shops should take into consideration when bidding jobs. It is also important to include hidden costs, such as printer maintenance, inks, and utilities. For shops that haven’t dipped their toes into the wide-format pool yet, here are some tips and tricks to keep in mind.

Wide-format printer software & design tips

When working with a client to print banners, backdrops, or booth graphics on a wide-format printer, it is important to understand the differences between the various types of color spaces, such as CMYK, RGB, or spot colors, and file types like vector and raster and where each of these might be used, said Scott Burgess, Roland DGA East Coast Imagination Center manager.

“Are you printing corporate logos or photographic images? Knowing your expected output and its relationship with the files you are creating or receiving from the customer is critical for producing high quality output,” he said. “For example, if a customer sends you their company logo, they are going to expect that you match the colors as closely as possible, so they might be using predetermined spot colors like Pantone. You will need to understand the limitations of your output devices so you can work within those limitations or communicate with your customer.”

David Lopez, product manager, Professional Imaging, at Epson America, said that vector graphics are the easiest for print shops to work with and can be resized without losing quality. “These files ensure flexibility with image size and can be enlarged to encompass a backdrop or large booth graphic,” he says.

It is also important to leverage high-quality design software, such as Adobe Illustrator, for optimal results. Lopez said it is best to save files as high-quality PDFs to facilitate a smooth transfer from graphics design to RIP software.

Calvin Berry, project manager for Denver Print Co., said that color ends up being one of the biggest challenges his company faces when working with clients. Many of them submit files in RGB because that is the color scale that most people see on their screens, but his wide-format printers print with CMYK.

Denver Print Co. relies on Pantone to create that bridge between RGB and CMYK colors, “but it is pretty difficult without doing a post-press proof,” he said. If something is important enough to color match, the print shop should sit down with the client and compare their RGB color scheme with several Pantone colors that are similar and then print them out to do a visual comparison.

Most people don’t understand color systems and how they work so it is important to be as honest and straightforward with clients as possible, Berry said. Make sure their expectations are realistic.

Burgess added that a customer may want its logo to be printed on an 8” X 10” easel back sign for a counter, but that same logo might need to be used for a 4’ X 8’ banner they are going to hang in their lobby. “So, while a JPEG file of the logo grabbed from their website might be fine for creating the small print, it won’t be suitable for a large banner,” he said.

“Communicating clearly and effectively with your customer is also key,” said Burgess. “Find out what’s important to them before you print their job and, if necessary, provide a proof for them to approve. For instance, you might be called on to print an image with a variety of elements (photographs, text, company logo), but if you have poor communication with the customer, you might never learn that the only ‘color critical’ component of that print is the colors of their logo.”

Lopez added that “when it comes to design, it helps to best understand the printer’s full capacity. When working with an Epson wide-format printer, designing in RGB rather than CMYK yields more vibrant color outcomes.”

Epson printers are known for their extended color gamut, with some models offering an array of colors outside of CMYK, including red, gray, orange, light magenta and light cyan, that showcase their full impact when utilized within the RGB framework, he said.

Denver Print Co. has a roll-to-roll solvent press for vinyls, banners, stickers, and billboards. It also uses dye sublimation to infuse printed film onto fabric for backdrops at trade shows, stretch fabrics and canvas-like materials that are made from polyester/nylon blends. If the shop needs to use offset printers, it ships that work to another shop down the street. It also has an old Heidelberg machine to produce high-quantity posters and flyers.

“Each one of our machines uses its own color system, which makes it additionally tricky,” Berry said. “Depending on where the machine is, humidity can have a huge effect on color.”

Altitude can also impact printing. What comes off a machine in Denver might be completely different than what a machine in Florida produces.

Because each machine is different, it makes it even more difficult to color match, especially if a client wants the same color scheme on flyers, billboards, and fabric trade show booth graphics.

Besides color, most wide-format banners, booth graphics, and backdrops will require hem tape or sewing. To design a graphic for this type of output, Lopez said it is important to leave 1/2” around the graphic that will be folded over for a hem. He suggested designing the graphic with a box surrounding it that is printed out in a light color or dotted line to provide easy alignment post printing.

It is also important to consider where the banner grommets will be. The average banner is 3’ X 5’ and requires four grommets for hanging. Lopez suggested marking where the grommets will be on your design to ensure the design is evenly spaced.

“For print shops, there are programs, such as Epson Edge Print PRO, that offer features to benefit the design and print of a banner or large backdrops, such as wall tiling, that allow for a half inch overlap for precise alignment of printed panels,” he said.

Ongoing costs of operation

There are four basic costs associated with day-to-day printing: the cost of ink and media, the cost of the device, labor costs, and the cost of doing business, which includes rent, utilities, and insurance.

“Too often, in my experience, a new user will look at the cost of ink, media, and sometimes the cost of the machine and price their jobs based on those numbers, rather than looking at the overall cost of doing business,” Burgess said. “Factors like utilities, labor, etc., should be factored into each job. Another ‘hidden’ cost is the cost of reprints. For example, if the color turns out wrong, or the job is destroyed by your laminator, your ink and media costs may be double than what you originally expected. So, the most important rule to keep in mind is this: always price your jobs competitively, but with enough margin built in to cover all the other costs of doing business, including waste.”

It is important to consider the quality of the materials a shop is purchasing, Lopez said. “Using high-quality materials will yield high-quality results. Printers should consider that while purchasing less expensive materials can lower costs initially, it can lead to increased waste and reprints, ultimately costing more in the long run.”

Printer maintenance is a big one. Regular maintenance is essential to keeping the printer running smoothly. That includes replacing parts, such as printhead wipers, air filters, cleaning cartridges, and waste ink bottles.

Lopez pointed out that electricity consumption is something many shops neglect to include in their project bids but “in addition to the printer itself, a print shop must also consider additional energy costs related to maintaining a stable environment, such as air conditioning and humidity control through humidifiers/dehumidifiers and ionizers.”

If a shop uses a solvent printer, there is a cost to properly disposing the ink. “Solvent ink cannot be thrown away or flushed through water pipes,” he said. It must be disposed of through a specific waste disposal process, which is an ongoing cost throughout the life of the press.