Dryers and ovens are key pieces of equipment for any sublimation or decorated apparel business, with many features and benefits to consider. Previously, this equipment was ordered to fit the business’ needs at the time of purchase. Over the last couple of years, with new advancements and developments in gas burner technology and other supporting systems, this equipment is now a standard in any shop.

Let’s discuss what features to look for when looking at the gas ovens and dryers available for the graphics industry.

The gas burner

The gas burner is known as the “heart” of the oven and directly contributes to the gas usage and efficiency of the unit to produce the BTU needed for the graphics industry. For years, the only option was the line burner. These burners had fixed combustion air that did not modulate as needed when the heat/BTU requirements changed. They only regulated the gas flow, which meant that the air/fuel ratio was never optimized during use. The result was a “dirty” flue exhaust and higher emissions than desired.

The advantage of modern burners is the ability to control both the combustion airflow and gas flow resulting in an optimum air/fuel ratio. This means the oven/dryer requires a smaller BTU-rated burner — creating more efficient temperature control and lower fuel costs – typically, 25-30% savings.

Insulation

Almost as important as the burner is the ability of the oven/dryer to properly maintain the heat throughout the heating chamber. As with any oven/dryer, it is important for safety and efficiency to ensure adequate insulation. First, insulation keeps the body of the machine cool to the touch. This requires at least 2″ of insulation, preferably a triple wall construction, in the heating chamber to keep the outside cool. Any junction in the equipment where extension drones have been added should have at least 4″ of insulation. The idea is to keep the heat in the oven/dryer and not radiating out into the surrounding workspace.

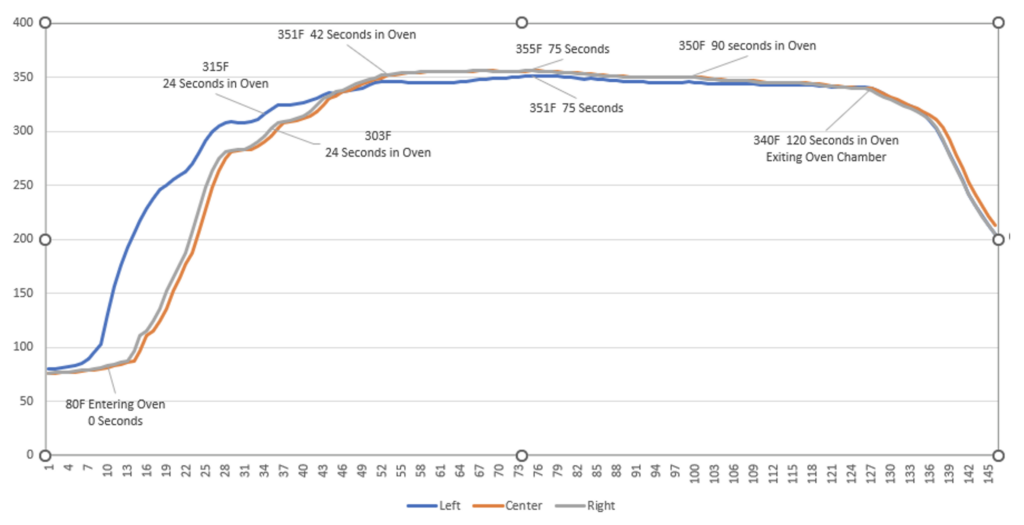

When appropriately insulated, the heating chamber can maintain even temperatures more efficiently. With this in mind, a new gas oven/dryer should be able to provide even temperatures within +/- 5 degrees F across the belt. An efficiently insulated heating chamber with a properly engineered airflow design should show a consistently maintained temperature throughout the length and width of the oven/dryer. (Fig. 1)

Control system

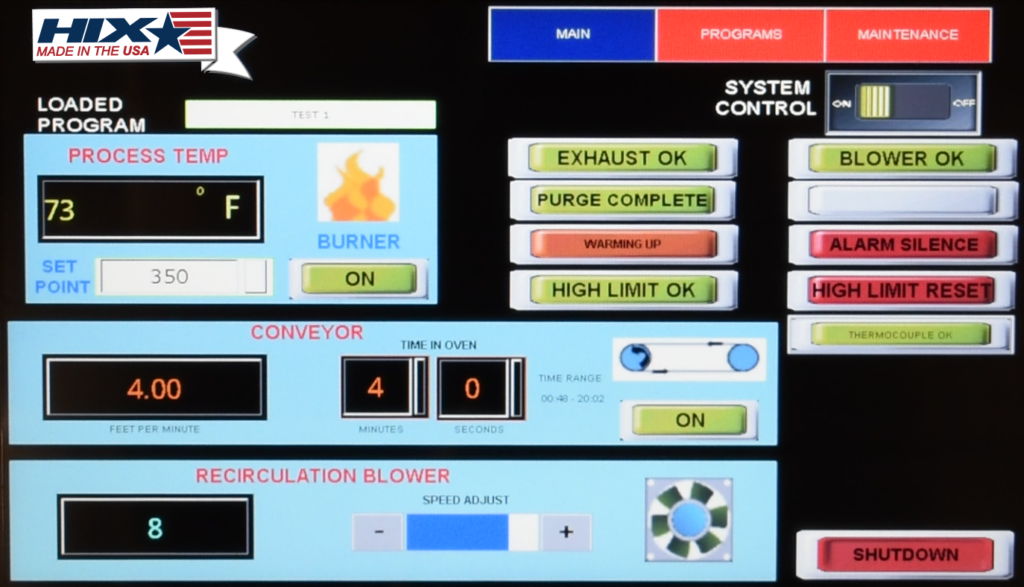

Any modern conveyor oven should have a touch screen HMI or (human-machine interface). Much like cellphones, tablets, and computers, this equipment is designed with the operators in mind. These new HMI systems allow the operator to view all the settings, maintenance, and troubleshooting information in one centralized location.

Many of these controls may offer features that can be incorporated into the programming. Some of the most common controls are:

- Preset programs

- Shutdown program

- Restart program

- Troubleshooting information

Tower light

A tower light is a standard installation on many of today’s large modern equipment. This light is placed so that it is visible from across the shop. Operators can easily look at the equipment and see if it is operating within the “normal limits” or if there is an issue that requires their attention. Most towers include a loud beeper to alert the operators if an urgent problem needs to be addressed. Some typical conditions and information you might see with a tower light include the following (Fig. 2):

Going forward

A dryer is a key piece of equipment and a major investment that needs to be carefully considered before purchasing. A well-designed and constructed oven/dryer can easily last 25-30 years with proper maintenance. A high-quality oven will cost a little more on the initial purchase due to many of the features we’ve discussed. However, these features and benefits will pay for themselves in lower utility and maintenance costs — often in less than a year. Just remember that these are only some of the key construction and design features to look for when considering a suitable oven/dryer for your business’ needs.