Dye-sub printing on textiles is a growing part of the industry because its applications are vast. From soft signage to clothing to furniture and sports equipment, the possibilities are endless. Throughout this article, you’ll see many examples of what can be done with a dye-sub printer, and in many cases, it’s far easier to produce than the fantastic end products would lead you to believe.

The first dye-sub printers

In the early days of dye-sublimation, it was a struggle for print shops to get into it because there were no dedicated printers specifically for that task.

“Everything was Frankenstein’d,” according to Gary Barker, Digital Technology Group. “You would retrofit your printer, use someone else’s ink or another piece of software. Today, several manufacturers are now manufacturing their own dye-sublimation printers, their own inks, and pairing them with known software. It is a lot easier for the end-user to get good consistent quality, and just the workflow process is much more streamlined.”

Tim Check, Epson America, agrees, saying that over the past decade, the dye-sublimation market moved from “cobbled photo and CAD printers to purpose-built sublimation printers with consistent output and high reliability.” The equipment available in 2021 ranges in output volume from sampling size to high-volume digital production, while the cost of equipment has come down, along with the operating costs, to only be “a small portion of the overall cost of the apparel production,” he says.

Epson has seen growth with digital textile print applications, and over the past 18 months, “there has been a shift from in-store to online purchasing. As such, buyers have significantly more options and customization in the products – apparel, decor, gift items. Digital textile printing enables designers to create and sell unique designs on a made-to-order basis,” says Check.

Another more recent change is that dye-sublimation technology has become easier to use and more affordable in-house. That has prompted many smaller shops or large apparel or home design companies to purchase their own equipment rather than outsource those jobs to Central and South America or Asia.

What that means for the client is that jobs get completed more quickly and with shorter lead and turnaround times. What would once have taken months to complete can now be completed in a week or less and be ready to deliver to clients across the country. This is important, particularly in the fashion and apparel industry, where designers couldn’t respond quickly enough to smaller opportunities or test markets.

“The advantage of dye-sublimation is you can start small and scale your business,” says Barker. Many get started with dye-sub printing by personalizing smaller goods like hand towels, golf towels, baby blankets, or jerseys.

“During the pandemic, there was a serious supply chain disruption for all parts of the textile and apparel industry,” says Victoria Harris of Mimaki, resulting in a “significant shift to DTC/e-commerce creating a democratized market for small business and brands to compete” and a shift to more localized manufacturing.

“There is a demand for a digital solution to create less waste and obtain faster speed to market, which digital textile printing aligns perfectly with, values being short-run production, greater variation of designs, vast customization, ability to create on-demand and support sales as they increase without having to stock large inventory which are at risk of costly meltdowns down the road,” she adds.

Textile printing technology

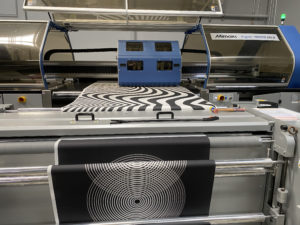

There are two types of textile printing technologies, transfer dye-sublimation and direct-to-fabric printing. According to Harris, transfer dye-sublimation is very popular, especially among newer print shops, because it is a fairly easy process to learn.

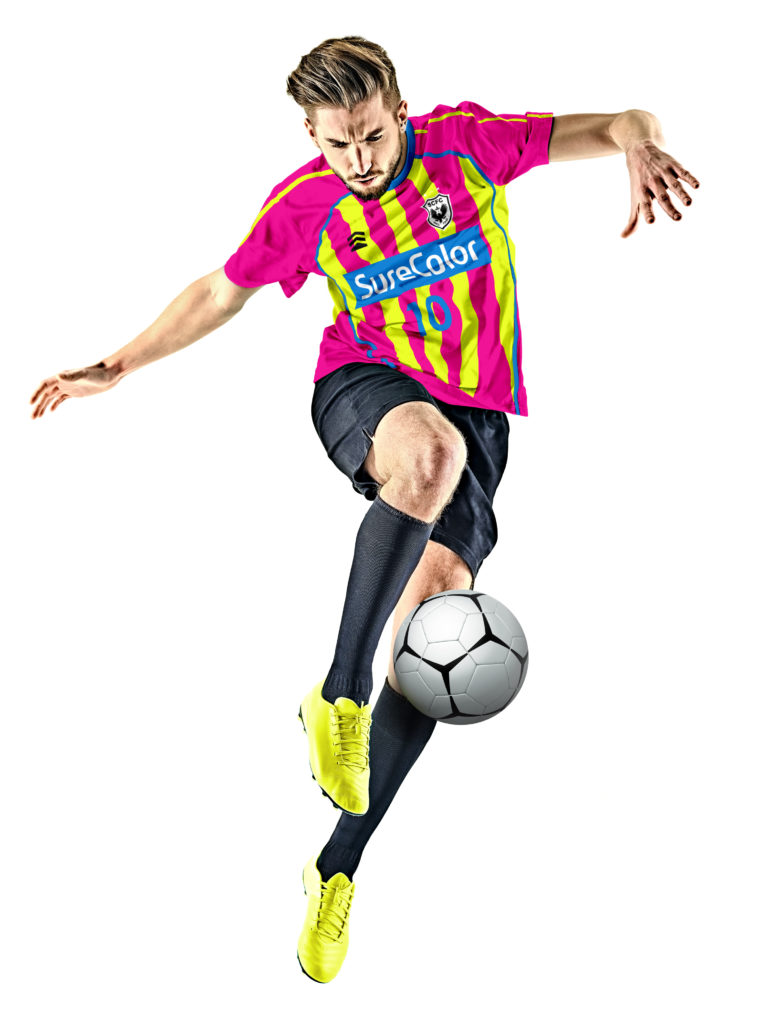

Dye-sublimation is used for polyester materials and sportswear. The design is printed onto transfer paper and then sublimated onto the fabric using a heat press.

The difference between printing with pigment inks and printing with dye-sublimation is that dye-sublimation actually dyes the fibers making it wash and rub-resistant, whereas pigment inks are just laid down on the surface of the material, making them more susceptible to washing, fading, and cracking, says Lily Hunter, Roland DGA.

Many polyester fabrics have the look and feel of linen or cotton, which has fueled demand for these products in the apparel and home decor industries, including athleticwear, athleisure, bathing suits, cushion covers, and table linens.

With dye-sublimation, customers don’t have to worry about the ink on their furnishings transferring to their clothing.

“Digital printing has a nice advantage. We reduce lead times, increase efficiency, and can do it on demand,” Harris adds. “You don’t have to order 30,000 units like you did before. Now you can produce 100 to 1,000, and whatever sells, you can make more of instantly.”

For direct-to-fabric dye-sublimation printing, a shop needs coated fabrics to hold the ink before it goes into the heat or steam press. If the material doesn’t have a coating on it, the inks will bleed. If the fabric is for apparel, it also needs to go through a wash cycle to remove the coating.

In both transfer dye-sub and direct-to-fabric dye-sub printing, inks look very dull during the sublimation process until heat and pressure are applied.

That’s when the solid ink particles turn into gas, and the gas penetrates the polyester coating or fibers, but it is the pressure that helps the color bloom, Hunter says.

Markets for dye-sublimation

Dye-sublimation printing is very versatile and can be used for soft signage, apparel, home decor, and promotional items.

The soft signage market is growing, but it is more “popular in Europe than in the states because in Europe PVC is outlawed. They can’t do banners there. They have to do soft signage,” says DTG’s Barker.

In the U.S., silicone edge graphics have become very popular, especially in airports with numerous backlit advertising or informational displays. Instead of using films in those lightboxes, airports turn to textile dye-sublimation because the fabric can be front-lit or backlit, depending on the application. Fabric is easy to install, is more forgiving, durable, scratch-resistant, and lightweight, making it easier to box up and ship around the country. Trade shows have also started using more dye-sublimated soft signage in place of vinyl banners.

Apparel is also a fast-growing market for dye-sublimation. It takes print shops to a new level because it involves printing on textiles, cutting them out, and sewing them together.

“Much of that is coming back to the states just because you have the ability to do shorter runs. Event- and time-sensitive driven projects can be done much faster and with the same level of quality as they are when they are exporting projects,” Barker says.

Check added that “as more designers gain experience with digital design and the virtually limitless possibilities of sublimation, we expect to see sublimation have a major impact for years to come.”

Learning curve

For print shops new to dye-sublimation, the process is much simpler than it used to be. When deciding to enter this market, it is essential for a shop’s staff to understand each machine’s full benefits, uses, and capabilities to help them meet increased demand, says Check.

“When looking for an entry-level dye-sublimation printer, consider its versatility and ink technology. Dye-sublimation requires exceptional color saturation and high contrast, so it is beneficial to find technology that offers high-density black ink to ensure output has excellent tonal transitions and grayscale,” Check says. “By incorporating digital printing technology equipped with new feature sets and ease-of-use benefits, today’s apparel decorators can expand product offerings to better fulfill orders, provide quicker turnaround times, and meet the growing customer demand.”

Barker adds that “there are nuances to dye-sublimation that are different than other traditional methods of printing, but it is not something people should be afraid of.” He suggests making an informed purchase decision by buying the right type of equipment for your business and purchasing that equipment from a company that can support and train your staff on various workflows, business concepts, and projects you want to develop.

“If you purchase the right equipment from the right company, you can eliminate many of the pain points of getting into dye-sublimation,” Barker says.

Hunter tells people wanting to get into this print process to outsource their sublimation projects at the beginning to build up their business first.

“Even if you know how to print, like on an eco-solvent printer, sublimation is a different animal. You can print, but the big learning curve is learning the heat press and finishing,” she says.

Shops should also make sure they have enough space for the printer and heat press because you don’t want the heat from the press to dry out the ink in the print heads.

Dye-sublimation needs to take place in a temperature- and humidity-controlled environment. The type of fabric used is also important.

Shops need to realize that fabrics, even when purchased from the same manufacturer, can have different weaves, threads, and fibers, which take to dye-sublimation in different ways.

“If you are going around shopping for the cheapest fabric, it can perform very differently, and your result can really be different in colors, in feel, the washability, even the stretch if you get some cheaper materials,” Hunter says. “They don’t hold stretch or recover from stretch, or if you have a snag, the way they are woven may not have a stop rip function.”

Screen printers wanting to get into dye-sublimation will have a different learning curve because they will have to learn the digital printing side of the equation even though they are already familiar with different fabrics, Hunter adds.