A great thing about lasers is that they can be used to engrave and cut products for nearly any market. You’re not relegated to selling to just one audience. Today, businesses seeing success are the ones who continue to diversify their product line to attract new customers and open new revenue streams.

If you’re looking for new audiences to target, consider the following markets and laser applications.

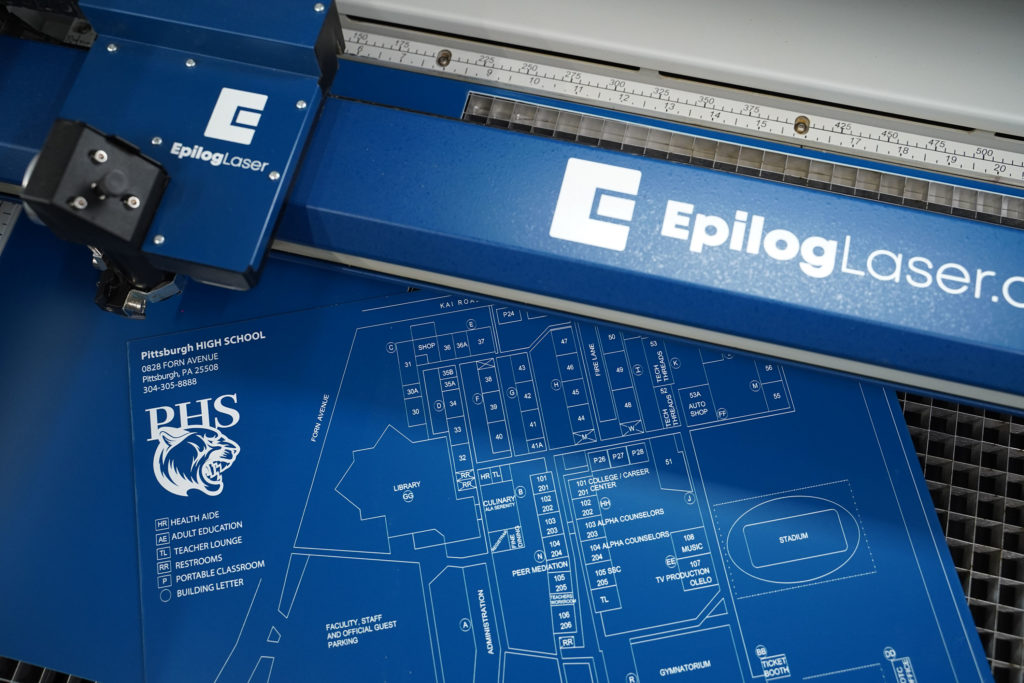

Signage

This is probably one of the most profitable alternative applications for engravers looking to expand.

Regardless of industry, everyone needs signage. Whether it’s practical wayfinding or directional signage, or intricate and dynamic displays, every business and organization needs some type of signage.

Plus, there are always new laser-friendly signage substrates being developed. Having a laser allows you to cut and engrave impressive signage for any environment.

Industrial marking

This is a great market that engravers can target for several reasons. Popular industrial marks include bar codes, serial numbers, 2-D data matrix codes, and logos on products. These marks can be used for identification, tracking, quality assurance, branding, and asset protection.

Manufacturers often need to brand or serialize many identical parts, so engravers can easily load up their engraving bed or jig and enter the variable data to mark an entire table of tags, parts, or tools—a profitable high-volume job.

Industrial jobs are also often more consistent than one-off projects. Manufacturers may need to mark parts or components regularly—monthly, quarterly, semi-annually, etc. Getting these products into your regular rotation of jobs can be an ongoing revenue generator for your business.

CO2 laser engravers/cutters can work with coated metals like painted brass or anodized aluminum. They are essentially removing that layer of coating or anodization to expose a contrasting color underneath. However, if the industrial marking job requires marking bare metal (either with an annealed, engraved, or polished mark), a fiber laser will be required. A CO2 *can* mark bare metals; however, a metal marking compound like Enduramark is necessary. In this process, you apply the compound, then laser as normal, and wipe away the excess with a damp cloth. In this case, the laser bonds the compound to the metal, resulting in a permanent mark—no material is actually removed. It’s easy enough to do, but if you’re marking enough metal, adding a fiber laser to your business may be warranted.

Breweries/Distilleries

While not traditionally thought of as a top market for the laser industry, by focusing on a niche industry like breweries, businesses can expand their client base. These businesses sell and give away a lot of swag to build awareness of their beverages and brand—think engraving promotional products like coasters, growlers, pint glasses, mugs, and water bottles. Custom beer tap handles are also a great offering.

Breweries and distilleries rely heavily on exposure, and their logo should be on pretty much everything they sell and give away.

Profit potential

Calculating the profit potential of expanding into new markets can be tricky because so many factors are involved. Before you determine your pricing structure, we recommend learning the prices of other engraving businesses in the area. It’s a good way to gauge the amount customers are willing to pay for engraving services, and it will help you determine a competitive price for your services. As you determine your pricing structure, consider the following:

- Minimum charge – covers the time of job set-up.

- Artwork charge – covers time for creating any logos or artwork.

- Materials cost – covers the cost of all related materials.

- Number of items – calculate the time it takes to engrave each piece of the job.

How much you make on new applications is ultimately dependent on the market you are selling to and the amount you need to earn on the job to make it profitable enough for your business.

If you’re considering expanding into new markets or broadening the scope of your laser applications, practice makes perfect. Load up on blank/practice pieces and really dial in your laser parameters and technique. Then, create an arsenal of great-looking samples to add to your website or showroom.

Whether it’s for branding, recognition, or identification purposes, the demand for laser engraving and cutting services continues to grow. By targeting new markets, not only can you expand your customer base, but your profit potential as well.