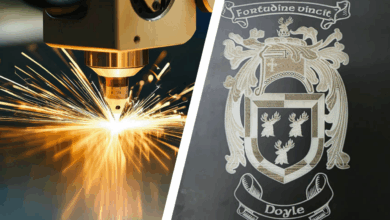

In my opinion, the CO2 laser is one of the most cost-effective and fastest ways to engrave mirror products. Abrasive etching is also an excellent method, but the extra cost of a photomask and the time required to apply and remove the mask cannot compare with the speed and cost of using a CO2 laser.

Mirror products have a backside (non-mirror side) coated with a very thin layer of silver, then a thin layer of copper, and finally sealed with a protective paint layer. The CO2 laser removes all three of these layers instantly by vaporizing them. No masking or part protection is required. While many laser engraving professionals leave the laser-etched piece plain, others apply a layer of black enamel paint (or any other color) over the etched backside of the mirror. CO2 lasers are a great method for etching mirror coasters, beveled mirrors, and mirror ornaments.

For laser-engraved coasters, the dark part of the image is where the laser removed (vaporized) the mirror backing, and you can now see through the glass. By removing the mirror backing with the CO2 laser, you are left with only glass instead of mirror. Use only enough laser power to remove the mirror coating, as you do not want to etch the glass.