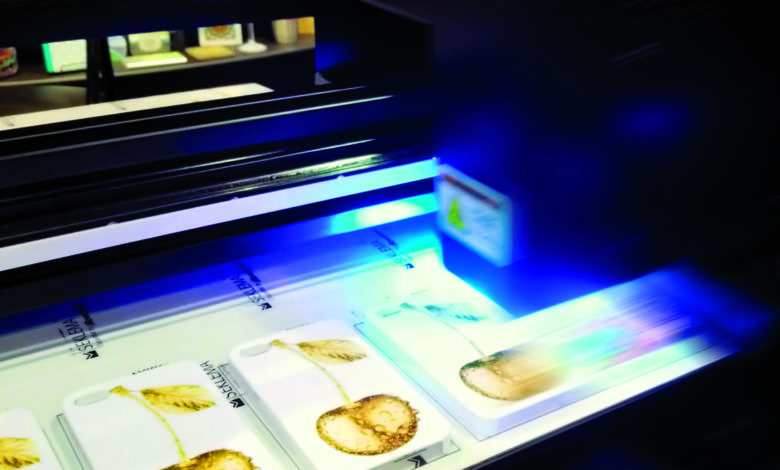

UV printing is a fast-growing segment of the printing and customization industry. This printing process spans many sectors, from industrial manufacturing to home-based businesses. With any piece of equipment comes necessary care and maintenance, and some questions to ask yourself are:

- With such a wide range of applications, what are the best practices for maintaining these expensive machines?

- Who should be responsible for the daily care?

- Can the substrate you are printing on effect how often maintenance is required?

- Can the types of inks in the machine affect how often maintenance is needed?

- What products should I use when performing maintenance?

- What are the dangers of UV printing that can damage your printer?

Identify who does what

As a field service technician with 23 years at PDS Equipment, I am going to give you some insight on the things I see on the job, and what it takes to make sure your machine is properly maintained.

The daily care of UV printers should fall primarily in the hands of the trained daily operator. In-house service technicians should be the second line of defense. The regular operator has the most intimate understanding of the machine. They run it day in and day out.

Your operator should be trained well, along with whoever is in the supervisor role. I like to teach both the operator and a supervisor on a new install. This is a good practice I see used because if you lose an operator, you have a supervisor to train the newly hired operator. This point brings up a huge issue I see when helping shop owners, which is a lack of training. When you are considering what machine you are going to buy, and from which company, consider training. I typically train on a new install for 12-16 hours. I would not be OK with a phone install where the machine is shipped, and no one ever comes on-site.

Understand your printer

There are some rules to follow around the UV printing process. Poor practices can result in damage to your machine. One of the things you should know about your printer is what the maximum head gap is? What is the maximum distance I can have between my print head and my substrate?

This can vary depending upon the manufacturer. If you exceed the maximum head gap, the machine will produce an excessive amount of ink misting. This excessive ink mist sticks to everything causing components to fail prematurely. This also includes a bleed. If you need to print off the edge of an object like a phone case, for example, it needs to be in a jig. Now, the jig doesn’t have to be a CNC cut piece of aluminum; it can be as simple as a block of wood between the phone cases. This does two things: it catches the excess ink, and it keeps the UV light from reflecting back to your print heads. We want to control the light from bouncing around with jigs and fixtures because excessive UV light will damage heads and cause nozzle loss.

General maintenance

The frequency of maintenance on your machine often depends on what you are printing on. Products that are not flat may produce more ink mist requiring more frequent maintenance by your operator. A good rule of thumb is to do your maintenance at the end of every 8-hour shift.

Follow the machine manufacturer guidelines. Only use the prescribed chemicals in the maintenance procedure. Also, make sure you are using polyester cleanroom-certified towels and swabs. Lint and dust is your enemy.

If your machine has a printable primer being jetted out of one of the channels, sometimes that calls for a different cleaning solution. This is the case with the machines I service.

Maintenance starts at the beginning of a shift with a simple test print. If you have a good test print with no dropped nozzles, you may begin production.

After a full shift, its time to do your daily maintenance. I like to start by cleaning the underside of the print carriage first, using the prescribed cleaning solution and polyester wipes and swabs. I do that first because the heads are next, and I don’t want to drag any debris from the carriage onto the print heads.

When you clean the heads, make sure the wipe you’re using is clean. The wipe should be liberally wet with the cleaning solution before wiping the print head. Any ink that has been cured on the print head surface must be removed. This will only get worse with time, so get it all off.

Then, move onto the capping station and wiper. The capping station seals the head from the outside environment. The wiper touches the head in the cleaning process throughout the day, so keep both clean and replace the wiper as recommended.

These machines will produce for you consistently if you take the time to perform these steps. You shouldn’t be intimidated by this equipment. I train people with next to no printing experience who yield great results and profits for their businesses. The margins these machines can make you is impressive. So don’t let the intimidation of this process stop you. You can do it with just a little bit of training and support from a good company. I believe in the potential of UV printing because I get to see it first hand.

I hope sharing the good and bad practices related to UV printing is helpful and that my experience can help ease any fears you have around the printing process and the printer upkeep that comes with it.