One of the frustrating things about screen cleaning is the struggle to remove ink stains from the screen thoroughly. I have some specific thoughts in this regard:

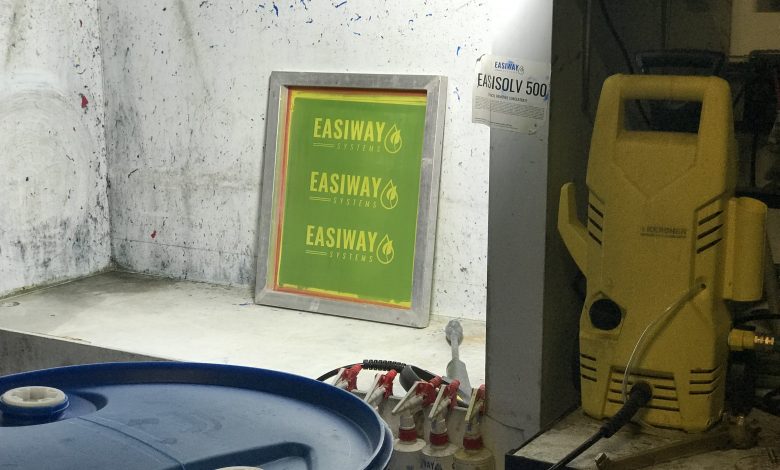

How you clean the ink affects how easy or difficult the stain removal can be. Harsh solvents like screen opener, lacquer thinner, mineral spirits, parts washer solvent, and products with heavy citrus derivatives create more difficult stains. How do you clean the ink without creating a problematic stain? Wipe the ink out with a mild and safe solvent. To remove ink in the washout booth, try using a screen wash/stain remover combo. You want something that works quickly without causing damage.

After you remove the ink and emulsion, you face the problem of a slight image remaining on the screen. In an ideal scenario, apply a mild solvent that’s non-caustic and non-toxic. These types of ink removers are better for you, your employees, your screen mesh, and the drain it all ends up in. A simple flood rinse will degrease the mesh, and no specific degreaser is needed.

Other issues cause stains to be more difficult:

- Extreme squeegee pressure and zero off-contact can drive ink further into the mesh knuckles.

- Water-based, UV, and solvent-based inks can produce a more difficult stain than plastisol.

- Tape residue mixed with ink can create a difficult combination to clean.

- Run-length also contributes to the issue.

- A 20,000-piece run is undoubtedly more complicated than a 48-piece job.

Some of this you can control and some you can’t. The lesson here is to control those aspects that you can to make the job more manageable in the end and try to use the safest products that get the job done. There is no doubt a highly caustic stain remover will remove the stain, but a safe alternative might just as well and be mild enough for handwashing.