What in the world is a placket? Grab your nearest sports jersey, button down, or polo and we will tell you! The placket is double layers of fabric that hold the buttons and buttonholes in a shirt. It is always made of multiple layers of fabric, and most include interfacing for support and strength.

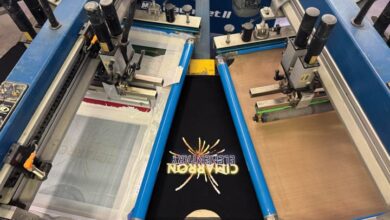

There are two ways you can go about printing placket shirts. You can buy a pre-made placket printing platen (which can be used with a manual or automatic press) or you can make your own. Trying to print without one of these options is going to prove to be a real mess as the ink won’t adhere to the buttons. The purpose of these platens is to allow the button and hem assembly to fall into the slot to eliminate interference with the squeegee. This creates a smooth flat surface to print on, which is ideal.

The key to printing placket shirts is to start with your artwork and art separation. Divide the artwork in half during the color separation stage or simply cut the film positive in half. Be cautious with the latter option, especially with multiple colors. Once your artwork is divided and your platen is assembled, you can spray the platen and load the garment like you would with any other printing job.

—Texsource Screen Printing Supply