Apparel decorating is experiencing a dramatic shift toward vertical integration, driven by the rapid adoption of direct-to-film (DTF) printing. Vertical integration means a print shop controls multiple stages of the production process in-house rather than outsourcing them. This move has given rise to the hybrid print shop: a model where decorators not only produce transfers in-house for their own apparel orders, but also sell those transfers to other businesses, expanding revenue streams while maintaining control over quality and turnaround.

In the 2025 DTF State of the Industry Survey presented by Keypoint Intelligence and sponsored by Roland DGA, 76% of respondents operate in-house or hybrid DTF setups, making vertical integration the dominant model. This includes 46% running in-house DTF production and 30% operating hybrid businesses. In-house operations produce DTF transfers exclusively for their own garment orders, while hybrid shops not only use transfers internally but also sell them to other decorators, turning production capacity into an additional revenue stream. Only 19% of businesses rely solely on purchasing outsourced transfers and heat pressing in-house.

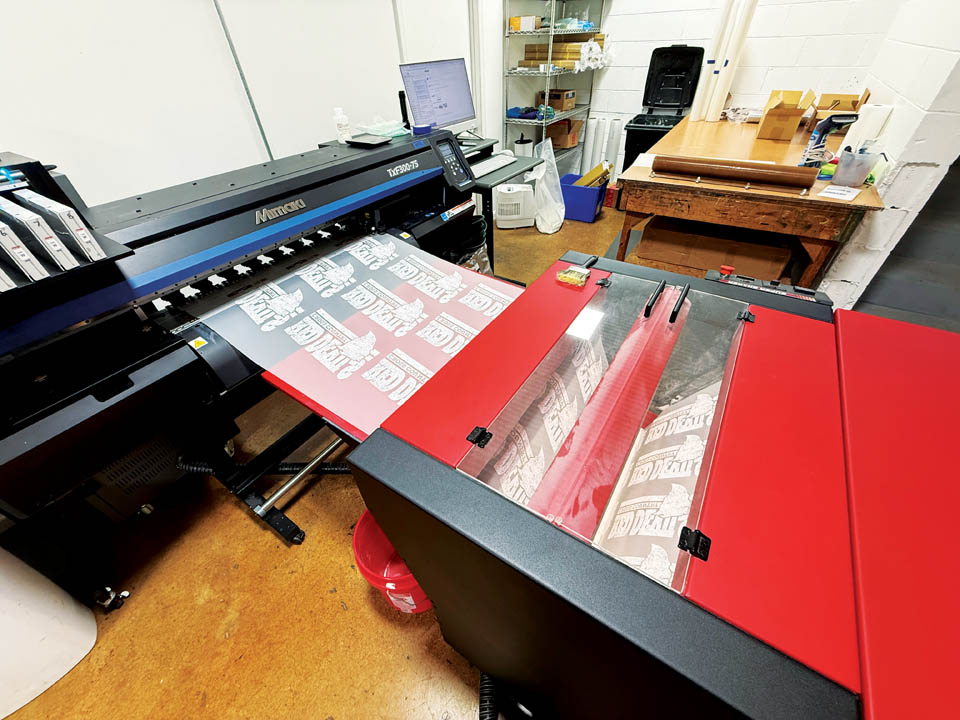

Kyle Robinson, co-founder and CEO of Print My Threads in Flatwoods, Kentucky, decided to bring DTF in-house after addressing a few key clients that were a good fit. “We needed the ability to print full-color designs in smaller quantities, but we also needed the ability to hit specific colors, so it made the most sense to invest in our own equipment and bring it in-house,” he said. “We then had several customers gravitate toward DTF because they no longer felt limited by the number of colors they could use in their designs.”

Print My Threads’ client base includes retail, hospital/medical, corporate business, nonprofits, and schools They’re starting to take on jobs from team sports because DTF allows for more customization and flexibility than heat-press vinyl. “We can offer a better product and produce it in-house,” Robinson said. “We recently did some warmup tops and bottoms that had a super smooth gradient fade in both the front artwork and the custom name and numbers on the back. Historically, this would have been a job we would have passed on and recommended they find someone offering cut-and-sew sublimation.”

Print My Threads’ client base includes retail, hospital/medical, corporate business, nonprofits, and schools They’re starting to take on jobs from team sports because DTF allows for more customization and flexibility than heat-press vinyl. “We can offer a better product and produce it in-house,” Robinson said. “We recently did some warmup tops and bottoms that had a super smooth gradient fade in both the front artwork and the custom name and numbers on the back. Historically, this would have been a job we would have passed on and recommended they find someone offering cut-and-sew sublimation.”

For certain projects and hard-to-print fabrics (or locations), Robinson and his team of 10 employees will now gravitate to DTF as the preferred print method. “Because of DTF, we can go into those jobs with confidence knowing the final result is better than what we could have achieved with screen printing or embroidery.” He said communicating the strengths and weaknesses of the DTF decoration process to his customers is key.

Print My Threads has also completed a few jobs that have combined DTF and screen printing. “We had some nice retail hoodies that required a smooth gradient fade in addition to a high-color, high-detail graphic with super tight registration,” Robinson said. “We ended up screen printing the gradient fade and then heat pressing the transfers just above. The screen-printed fade in the water had no feel and contrasted with the polar bear head just above, which was slightly raised from the DTF transfer. You could feel the variance of the open areas in the design and the transfer, giving the final print an elevated, dimensional feel that was interesting and seemed high-end.”

Print My Threads also sells transfers to local customers and through Stream, a platform developed by DecoFlo to connect customers with local and nationwide small businesses offering DTF transfer services. Customers can upload their designs, receive real-time feedback on resolution and quality, select the desired quantity, and place their orders. The platform prioritizes local shops, promoting community businesses and ensuring quick turnaround times.

“We’re currently not set up to be profitable doing high-volume contract DTF transfer printing, but we’ve had success selling through the Stream platform and for a few local and regional clients who we’ve vetted,” Robinson said. “DTF printers work best when being run daily, so it’s nice to supplement our own work by printing for other people.”

7 reasons screen printers are moving to an in-house or hybrid setup

1. Faster turnaround

1. Faster turnaround

- The 2025 DTF State of the Industry Survey shows that a quick turnaround is the top customer priority (66%).

- In-house or hybrid DTF eliminates shipping delays from outsourcing, allowing same-day or next-day production.

2. Greater control over quality

- Print quality was ranked the No. 2 priority (64%).

- Shops can monitor color consistency, adhesion, and durability directly, instead of relying on outside vendors.

3. Higher margins

- Producing transfers internally removes vendor markup.

- Hybrid shops can sell excess transfer capacity to other decorators, creating an extra revenue stream.

- On average, 42% of total shop revenue from those surveyed now comes from DTF products/services.

- For 8% of those surveyed, DTF makes up more than 90% of revenue.

4. Flexibility & customization

- Customization options are increasingly in demand, especially unique finishes, precise color matching, and variable sizes.

- In-house DTF lets shops experiment with specialty substrates and finishes without vendor minimums.

5. Reduced outsourcing challenges

- Decorators that rely on outsourcing transfers reported long turnaround times (14%), inconsistent quality (36%), and limited customization (21%) as pain points.

- Moving in-house or hybrid addresses those bottlenecks.

6. Volume growth & demand

- 42% of shop revenue on average now comes from DTF, making it worth the equipment investment.

- Apparel personalization and short-run orders require the speed and flexibility DTF offers.

7. Vertical integration trend

- Controlling more of the production workflow is a broader trend across print. It reduces dependency on outside vendors, safeguards against supply chain issues, and strengthens brand reliability.

Challenges to consider

DTF printing does come with operational challenges like:

- Equipment maintenance: 63% of those surveyed list this as a main challenge

- Color consistency: 57% cite this as a pain point

- Ink costs: 55% say this is a major issue

Robinson said his team at Print My Threads works really hard to maintain color accuracy, but as the inks, films, and powders improve, change, or go out of stock, they often have to make changes on the fly in order to get the best possible result.

“Color profiling is a moving target and something we’re constantly working on,” he said. “With screen printing, if you need to tweak a color, you tweak it and maybe change your mesh count, which is pretty straightforward. With DTF, the final color you achieve has to do with the machine you’re printing on, the firmware running your machine, the software you’re using to RIP your artwork, and the types of ink, film, and powder you use. If you change any one of these variables, your colors will change.”

Technology & growth outlook

- 73% of providers plan to expand capacity in the next one to two years

- 72% are exploring new technologies and inks

- 61% are interested in hybrid printing technology; 71% in new ink formulations

“As the films, inks, and adhesives continue to improve, and with the artwork set up properly, we’re able to achieve some pretty impressive results,” said Robinson. “I don’t think screen printing or embroidery is going anywhere, but there’s currently so much R&D being invested into transfers and heat press automation that I think DTF will continue to grow and become much more commonplace over the next several years.”

To better understand the companies surveyed in the 2025 DTF State of the Industry Survey, here’s a breakdown:

- 54% of businesses have one to five employees; 31% have six to 20

- The majority (54%) of shops have been in business for 10+ years, proving these are established shops adopting DTF, not just startups

- 95% serve the apparel market

- 70% serve promotional goods, and 68% serve sportswear, showing overlap between apparel and specialty printing

1.

1.