Every technology has pros and cons. And there are plenty of places you can go to see, read about, and compare different models or manufacturers.

You can find comparisons between DTG printers, like the DTG G4 from ColDesi to the Epson F2100 to the Roland VersaSTUDIO. You can also find resources comparing the OKI proColor 8432WT, 9541WT, and the Uninet iColor i560 white toner printers. The video above gives you a look at three completely different technologies compared to each other.

Comparing a Sawgrass SG1000 sublimation printer to the Epson model is great, but the first choice you need to make if you’re starting a custom T-shirt or customization business is what technology will best fit your business.

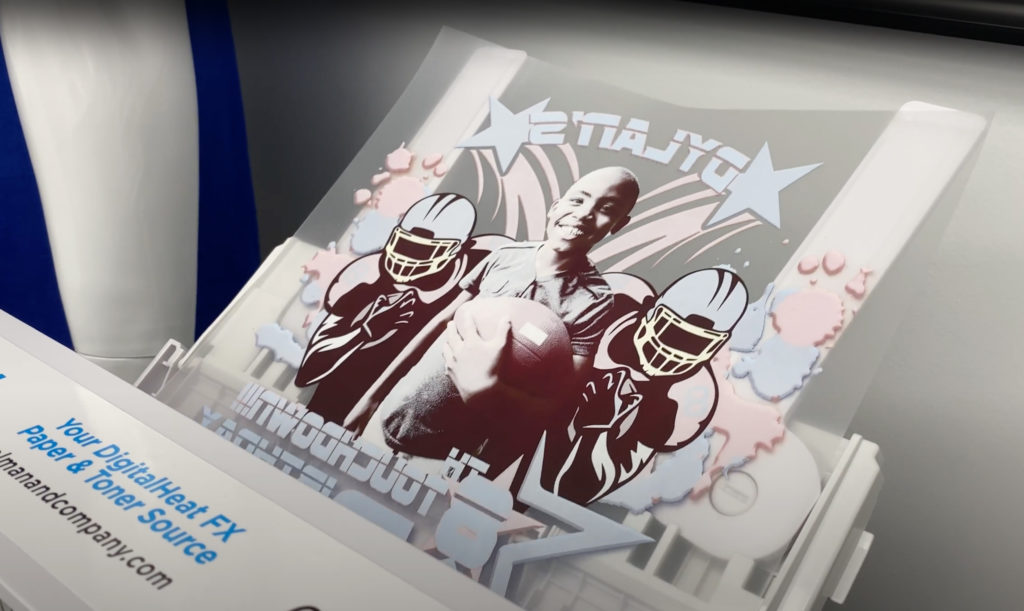

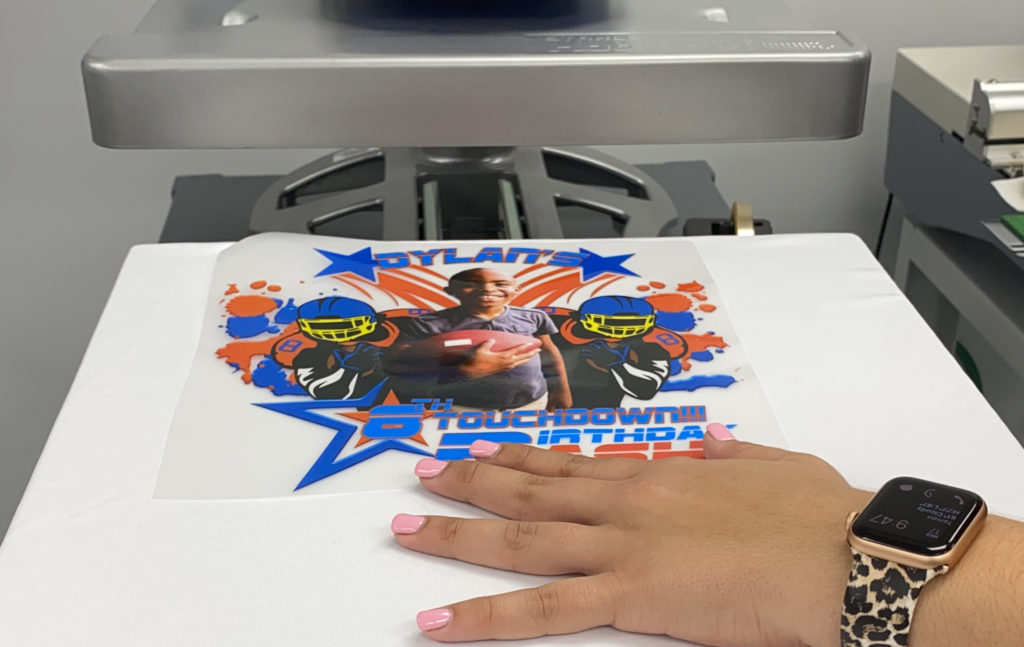

In this case, we printed the same image on the same white polyester shirt using:

- A Sawgrass SG1000 sublimation printer

- A G4 direct-to-garment printer

- And the DigitalHeatFX 8432 white toner transfer printer (OKI 8432 with Print Optimizer RIP)

All three produced some outstanding custom T-shirts with a bright, vivid image. And each piece of equipment has its own pros and cons, including initial cost, print cost, and flexibility of the equipment.

Equipment and prints compared

Sawgrass SG1000

Price: $1,500

The Sawgrass printer was the least expensive by far, coming in at around $1,500. You’ll still need a heat press just like with all these machines, but it’s much less picky about which one. So, including ink and paper, the total package usually ends up around $3,000-$3,500.

Quality: Excellent

This shirt feels like there’s no print on it at all, and it looks great.

Flexibility: Medium

You can really only use sublimation transfers on light or white items because the printers don’t use white ink. Sublimation only works on synthetic fabrics, like polyester, or hard goods that are specially treated.

You can decorate a wide variety of substrates, like T-shirts, mugs, and coasters, but they all must be sublimation blanks or 100% light-colored polyester.

G4 Direct-to-Garment Printer

Price: $19,995 MSRP

The direct-to-garment (DTG) printer has the same “I feel nothing” quality of the sublimation print, and it looks just as good as the sublimation print.

As you can see, it’s more expensive to get started. Typical starter bundles end up at right around $25,000.

These are larger, much more commercial pieces of equipment that print directly onto a shirt. No transfer printing required. The bundle price is much higher because you’ll also want a commercial heat press and a pretreat machine that’s used to prep the shirts for printing.

Supply costs are the lowest per print with direct-to-garment. That beautiful full-color print costs under $.80 to make — a tradeoff for paying more for the equipment upfront.

Don’t let that initial price scare you, though. Custom Ts are profitable, and since the ink cost is so low, you normally only need to sell about 50 shirts/month to make a finance payment.

Quality: Excellent

Like it says above, the DTG print feels just like that sublimation print — like nothing. It also has the same great washability and long-lasting color print. As you’ll see next, you get that same quality on more than just white polyester.

Flexibility: Medium

Yes, you can print on light-colored or white polyester with a direct-to-garment printer, but its sweet spot is printing on 100% cotton. Since it’s a CMYKW printer, you also can print on dark garments. The W in that alphabet soup description is white ink. So, you can print on white poly and dark or light-colored cotton Ts. It does not print well on black polyester and is very limited to the kinds of promotional products or hard goods you can produce.

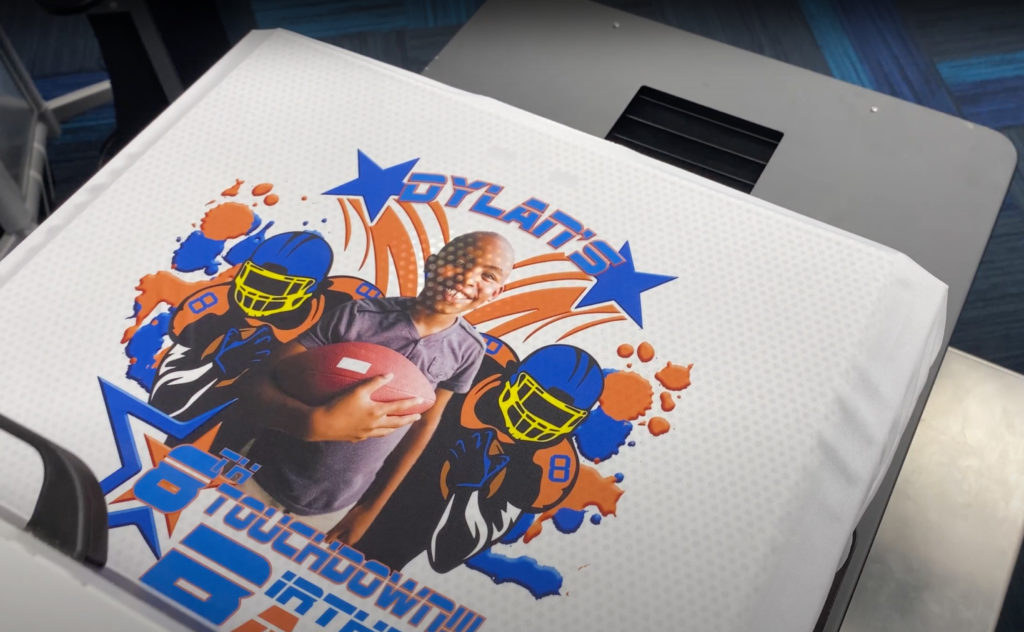

DigitalHeat FX 8432 (OKI white toner printer)

Price: $8,790 MSRP

DigitalHeat FX white toner printers normally end up costing between $10,000-$11,000. The additional cost comes from paper supplies, software, and a quality heat press that you’ll need to make great transfers.

As you can see, it rests right between the sublimation and DTG printer for cost, and financing is available for these.

The initial cost is in between the other two technologies, but the supply cost is the highest, with transfer paper being more than the sublimation papers and DTG ink.

Quality: Great

The polyester shirt decorated with the white toner transfers looked just as good as the sublimation and DTG prints. There are color differences, of course, because of the way each technology produces the image, but as you can see from the video, they all look great.

The one caveat to the white toner transfer print is that you can feel it. With DTG and sublimation, there is no texture or feel at all, but you can feel that something has been applied to the shirt.

This “hand,” as it’s called, will vary by the image itself. This graphic has very little white space, so the transfer covers a lot of area. If it were a more open design, you would feel the transfer less.

Flexibility: High

White toner printers are the most versatile printers. You can take a DigitalHeat FX white toner transfer and apply that to almost anything.

Custom T-shirts are naturally the most common application, and there are no limits to the fabric you can apply it to, from dark or light-color polyester to dark or light-colored cotton. White toner transfers also work for specially treated hard goods and dark poly or untreated hard goods and promotional products like tiles, neoprene bags, signs, jackets, and more.

The white toner printer also wins for flexibility because you can also sell the wholesale transfers themselves. Unlike DTG, where you must print on the finished product, there’s a big business in selling transfers to other custom T-shirt printers.

Choosing a printing technology

In the end, you have to balance the initial cost, cost per product, quality, and flexibility of each to figure out what’s best for you and your customers. And don’t rule out investing in more than one!

Watch the video, ask your questions, and take your time figuring out the right technology for your business.