Choosing the Right Rigid Plastic

Learn about the best uses for polycarbonates and acrylics for signage applications

Rigid plastics are found in many signage applications, but not every rigid plastic substrate is alike. This is especially true when looking at polycarbonates and acrylics. While both substrates certainly have their place in signage, choosing the right plastic comes down to the appropriate application.

A look at polycarbonates

When it comes to impact resistance, polycarbonates are a strong substrate that can stand up to high winds, hail and other outdoor elements, which makes it great for outdoor signage, says Jay Millhof, Polymershapes, a distributor of plastic sheets.

But that doesn’t mean polycarbonate has to be limited to outdoor applications. Given polycarbonate’s strong resistance to impact, indoor applications in busy traffic areas are also appropriate because they have to withstand the inevitable bumps that come with a crowd, Millhof says.

When creating imagery on polycarbonates, applying decorative vinyl is a popular option, and digital and screen-printing inks work well. While the expected longevity depends on the manufacturer, Millhof says, digital inks are formulated in a way that adheres well to polycarbonate.

“Some people struggle, especially with digital presses, when printing on some other plastics without some type of precoat,” Millhof says. “A precoat generally isn’t required with polycarbonates for most digital and screen-printing inks. It’s the nature of the resin, which is more receptive to ink than other plastics.”

If a sign shop needs to cut polycarbonate, it should be aware of the edges, Millhof says. Although polycarbonate is a strong substrate, if any notches are left on the edges after cutting, it could eventually crack, but using the right tools can prevent that from happening.

“I would go back and make sure you’re cutting with the right equipment and blade to avoid any notches,” Millhof says. “This is the most important thing to look out for when working with polycarbonate.”

Proper storage

Of course, to keep polycarbonate at its peak performance, proper storage is important. Polycarbonate should always be stored flat to keep the edges from bending or curling, Millhof says. Most polycarbonate sheets come with a masking material, but Millhof still suggests keeping the plastic covered, especially if it’s stored outside. A sign shop should also make sure that the polycarbonate lays on a fully supported surface.

“I have personally seen issues where people have stored their polycarbonate horizontally on something like a pallet that has very wide gaps, and the pallet will create waves over time that are difficult to get rid of,” Millhof says.

Even though pretreatment typically isn’t required for polycarbonates, sometimes static can build up on the surface in dry climates. This is also known to happen in northern areas during the winter. When static is a problem, Millhof recommends using a blower or wand that’s designed to help reduce the charge before printing.

Working with cast acrylic

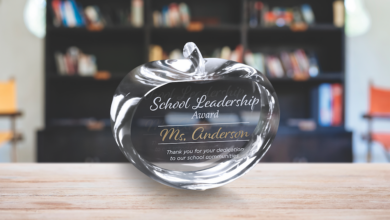

Cast acrylic is a versatile substrate that works especially well in indoor applications, says Colin VanLint, JDS Industries, a wholesaler for the awards, personalization, and signage markets. Although cast acrylic is susceptible to warping and discoloring outside, it’s popular in interior corporate spaces because of its elegant look.

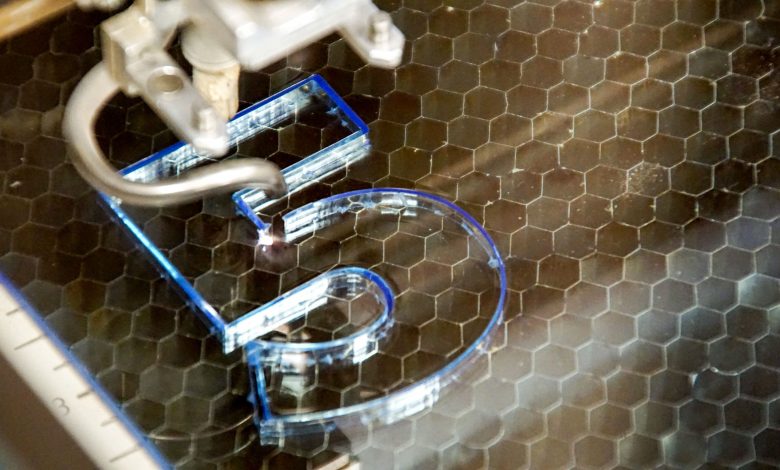

This is especially true when the acrylic is engraved with a laser, says Mike Dean, Epilog Laser, a manufacturer of laser engravers. Although other types of plastics are suitable for printing, acrylic works best with laser engraving.

“Cast acrylic is ideal for laser engraving because the laser gives it that frosted look,” Dean says. “You can easily cut the acrylic with a laser for a nice, polished edge, and it comes in so many different colors that you can create a variety of custom looks.”

Josh Robertson, market development manager for JDS Industries, finds having those color options is especially popular when creating interior ADA or wayfinding signage and clients want a distinctive system.

“We live in a world where everyone wants everything to be personalized,” Robertson says. “Using a custom acrylic sign gives you a unique look that helps you stand out from your competitor or any other business.”

When cutting cast acrylic with a laser, Dean recommends removing the protective paper from both the front and back sides. Some sign shops avoid removing both protective layers to keep the acrylic from scratching, but the substrate won’t cut as well. Considering that one of the aesthetic appeals of acrylic is those polished edges, a clean-cut is important.

How to care for acrylic

Caring for acrylic is simple, but a sign shop should be careful not to use any harsh chemicals, VanLint says. Some people think they need a cleaning agent with ammonia or alcohol, but that can leave the appearance of cracks throughout the acrylic. Instead, mild, soapy water will clean the acrylic without leaving any damage.

“If you use the right tools, caring for polycarbonate is a straight-forward process,” VanLint says. “You want to keep it out of direct sunlight because it will warp from the heat and use a microfiber towel to clean it. Try to avoid rubbing too much. Instead, using a blotting motion to keep the acrylic from scratching.”

Whether a sign shop needs a high-impact-resistant outdoor sign or elegant corporate signage, rigid plastic substrates offer great solutions. Polycarbonate and acrylic both have their place in the market and give sign shops the versatility they need to serve a wide range of client needs.