Few mediums offer the creative freedom of laser engraving. Highly advanced and versatile, laser engraving allows creators to flex their craftsmanship and woo customers of their craft with premium, personalized goods. From custom gifts and corporate branding to industrial compliance, the technology is making its mark.

“Engraving is one of the most versatile forms of customization available today,” said Corey Kelly, marketing manager at Trotec Laser, Inc. “It allows businesses to work across a wide range of materials such as wood, acrylic, metals, glass, and leather, all while delivering high-quality and permanent results.”

“Engraving also opens the door to product diversification and new revenue streams,” he continued. “A sign shop can add promotional products. A print business can offer personalized drinkware or awards. Even small creative shops can expand into corporate branding, custom gifts, or packaging enhancements.”

Driven by personalization and industrial use, laser engraving is the fastest-growing subcategory. Currently, the laser equipment and services market is estimated at $5 billion–$7 billion, with a global compound annual growth rate of 5%–8%. In the U.S., modest but stable 2%–3% annual growth is expected.

“As consumers continue to demand personalized experiences, we expect engraving to become an even bigger part of product design, packaging, and retail experiences,” Kelly added.

While shop owners are eager to explore the potential of laser engraving, it is an investment worth weighing. Industry professionals from Trotec Laser, Radian Laser Systems, and OMTech teamed up to deep dive into laser system options, innovation on the horizon, considerations before purchase, and maintenance – all of which influence a purchase.

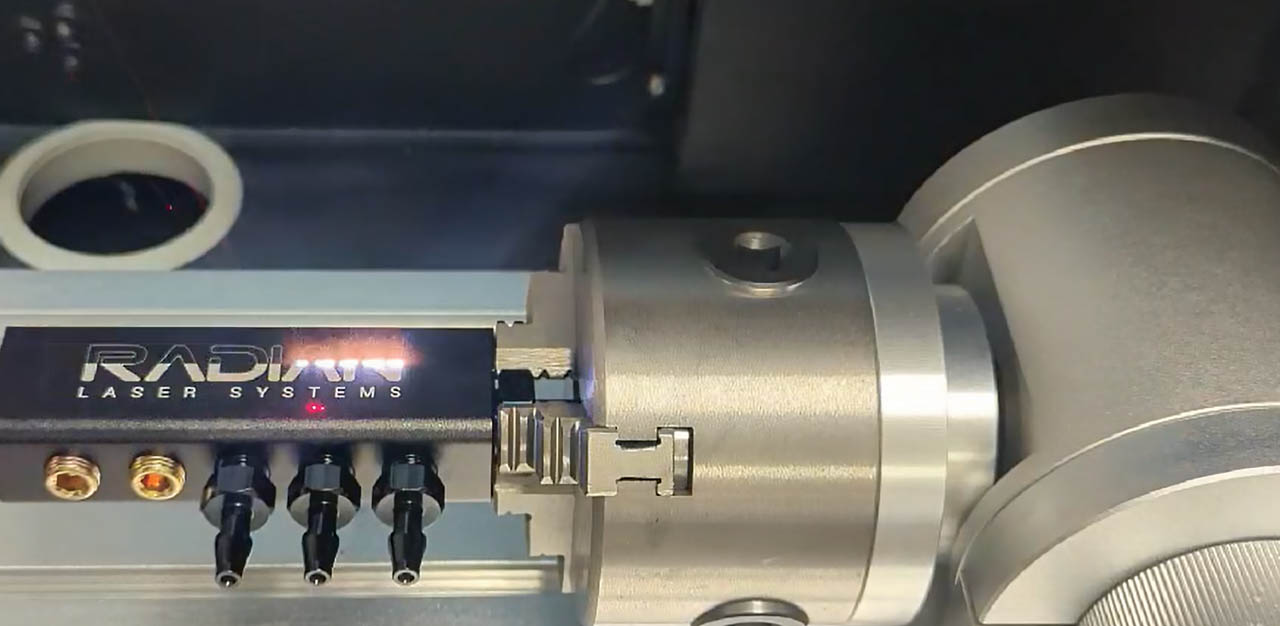

Galvo laser systems

Galvo systems use high-speed, mirror-driven galvanometers to direct the laser beam across a work area without moving the laser head. As such, the system exponentially increases the speed of specialized or high-volume marking and engraving by incorporating a Z axis into the process, according to Radian Laser Systems.

“The rise of galvo technology has reshaped what distributors are capable of producing – improving production speed, as well as quality,” said Avinash Garikiparthi, marketing manager at Radian Laser Systems.

The modern engraving community relies on galvo laser systems to perfect fine, intricate details on small, curved, and complex items or surfaces. The substrate choices are vast, and the quality is superior. From metals and plastics to fabric, ceramics, and even paper, galvo systems provide creators with various options to personalize. Common goods include jewelry and electronics; firearms, knives, and tools; serialization and logos; as well as medals, nameplates, and promotional items.

“Sports personalization is a hot topic right now. Being able to offer on-demand engravings for souvenirs at events is a great opportunity for businesses,” Kelly added.

In addition to capitalizing on consumer and awards markets, opportunities continue to expand in industrial sectors like automotive, medical, and aerospace. These segments require precise and permanent marking for safety, compliance, and traceability – boosting demand for engraving services.

“The opportunity to work with various applications and use cases allows owners to grow their businesses,” said Serena Wang, marketing manager at OMTech.

Galvo systems, she says, open the door for customization, automation, and production at a large scale. While this technology can serve both small and large volumes, it shines bright in integration and automation. With these features, business owners can streamline operational efficiencies with ease, while appealing to a broader customer base and personalizing diverse goods.

“For distributors running high-mix, high-volume orders, the difference in speed can either create a bottleneck or fuel expansion and growth,” Garikiparthi said. “With galvo lasers, you gain speed, accuracy, less wear and tear, plus the ability to produce at scale. It creates a better production experience for your team – and a better service experience for customers.”

In addition to producing consistent, high-quality results, the equipment eliminates outsourcing costs, unlocks more capacity with less downtime, allowing engravers to take on more jobs without increasing labor.

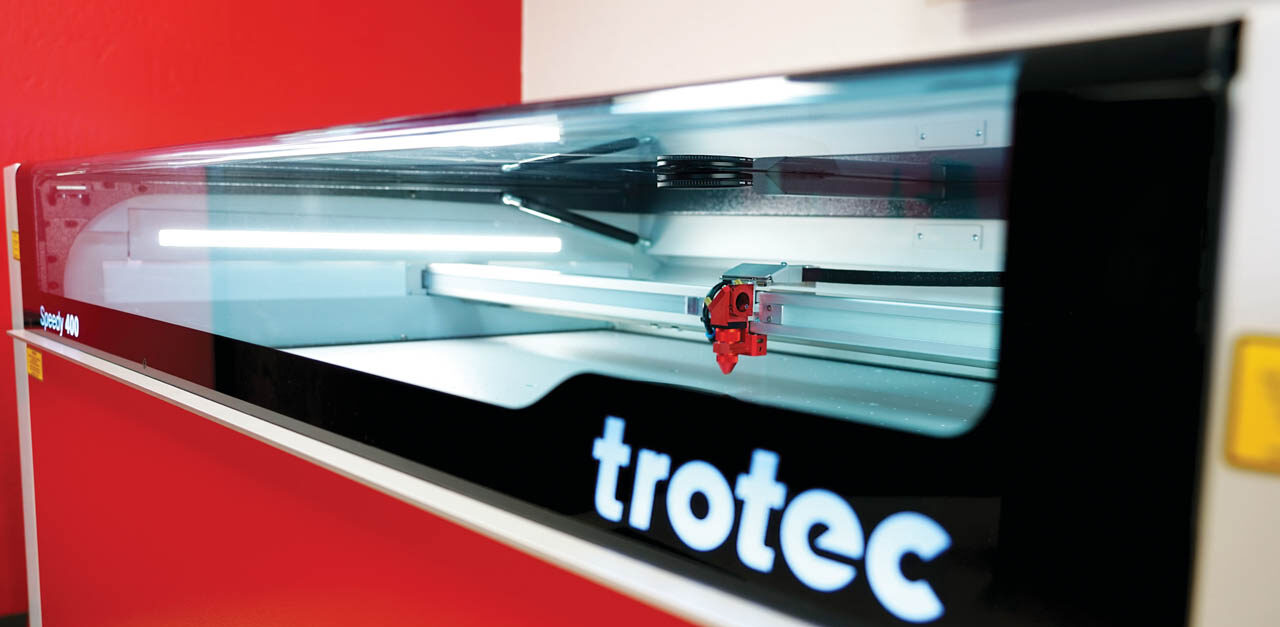

Flatbed laser systems

A flatbed laser system can use a CO2, laser tube, fiber laser source, or, in some cases, a diode laser source to generate its beam — depending on the materials or specific application. For example, industry professionals note CO2 lasers are common for nonmetals like wood and textiles, while fiber is popular for cutting and engraving metals.

Unlike galvo, the flatbed system relies on a gantry to physically move the laser head and optics to cut, engrave, or mark flat materials — covering a larger work area more effectively but at a more laid-back pace.

“The flatbed is a more straightforward device that will do the task at hand, but speed is limited and parts have to be replaced a little more frequently,” Garikiparthi said.

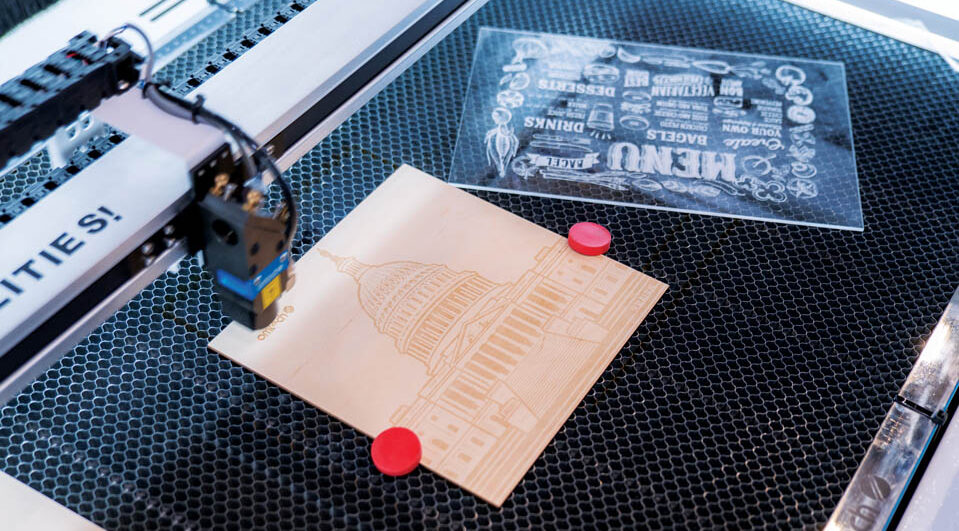

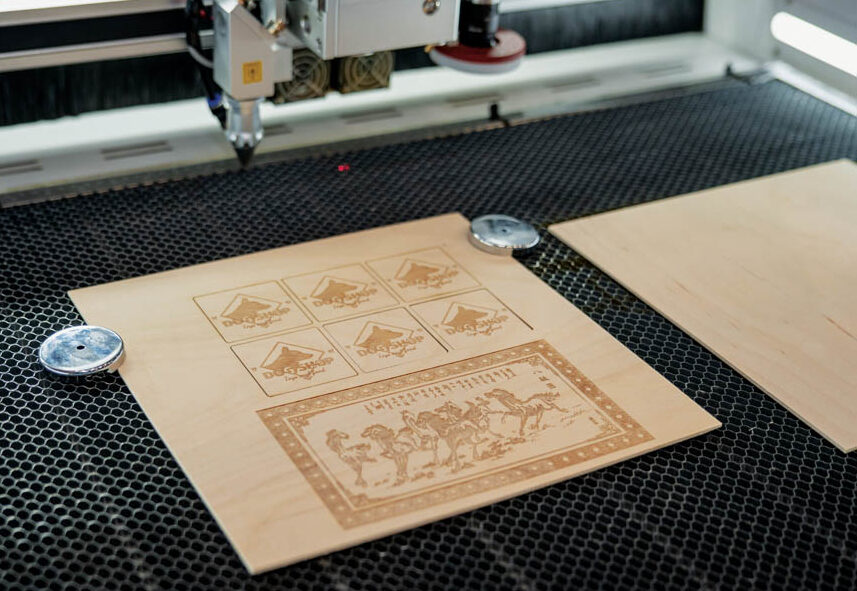

Simple but effective, engravers marvel at its ability to create flawless shapes in various materials like metal, glass, plastic, textiles, and even leather. The flatbed laser, featuring smooth cuts with minimal to no burrs, provides exceptional detail and finish at an attractive price point as well.

While galvo systems range from $25,000–$75,000 (or more) due to advanced components and capabilities, business owners can invest in a gantry CO2 laser system for $15,000–$45,000. As a result, Garikiparthi stated gantry-style options command approximately 70% market share.

“It is like printing presses, in that most users will start with a flatbed because of the price point, then once their needs evolve beyond the machine, they move to galvo technology for the gained speed and expandability — but that flatbed still will have unique applications and prove useful — thus leaving a hybrid setup,” Garikiparthi explained.

Flatbed lasers are available in a range of sizes, from compact systems specially designed for small-scale shops and tight workspaces to large-format machines that can handle full sheets

of material.

With a larger field size and lower price tag, the flatbed system is a common option for wide-format engraving and batch processing as well. It can accommodate 2D scale volume and large-scale production across a wide range of industries.

“Flatbed lasers shine when it comes to flexibility,” stated Kelly. “Their larger work area and ability to handle thick or flat materials like wood or acrylic make them ideal [for large-format pieces and a wider range of versatile applications], from signage and prototyping to personalization across many substrates.”

Together, Kelly said, the two laser systems complement each other: galvos deliver unmatched efficiency in marking and coding tasks, while flatbeds excel in versatility and creative applications.

Innovating for tomorrow

In a growing market, manufacturers are challenged to solve tomorrow’s problems today. According to Wang, manufacturers are pushing boundaries to create more opportunities for laser business owners to thrive. For example, OMTech stated it plans to incorporate both a flying galvo CO2 laser head as well as a CO2 laser

cutting head.

“RF laser engraving and flying galvo head laser engraving will bring speed and increased efficiency in production, while improving overall resolution, detail, and quality,” Wang said. “As a result, customers can enjoy the benefits of cutting and engraving quality all in one laser.”

Looking ahead, innovators remain focused on AI technology, as well as its impact on the industry at large. Smarter design workflows, batch processing, and real-time quality control are front and center, as well as seamless customization tools embedded directly into online shops.

“We’ve seen huge improvements in optics, software, and automation, which allow for greater throughput and ease-of-use. Modern systems also integrate more seamlessly into existing workflows, reducing setup time and human error,” Kelly explained.

He foresees continued momentum in automation and workflow integration, like camera systems for positioning and even robot-assisted marking for industrial environments.

“One of the most exciting developments is the integration of camera systems and smart positioning tools that make setup faster and more accurate. For example, vision-driven placement ensures designs are aligned correctly on irregularly-shaped or pre-cut parts,” Kelly said.

“We’re also seeing more automation features, such as robotic part handling or software integration that connects lasers directly to ERP or design workflows,” Kelly explained.

Garikiparthi is eyeing industry crossover opportunities. She expects to see even more engraving services merging with laser cutting, 3D printing, CNC, and packaging for end-to-end product production.

Sustainability is another key factor in the evolution of laser systems, as customers demand eco-friendly materials (i.e., bamboo and recycled wood) and clean engraving methods. Digital design integration not only allows for perfect replication of complex logos and images, but also boasts a noncontact process, reduces waste, and is environmentally friendly.

“In general, laser engraving is often seen as more sustainable than printed or chemical alternatives,” Garikiparthi said, noting laser engraving is devoid of inks and solvents.

Considerations before purchase

Before making any equipment investment, owners should study niche areas to specialize, substrates to explore, and new market opportunities.

“My advice is to think beyond your current product line and consider how engraving can enhance the services you already offer. Look at where your customers are spending money —promotional items, signage, gifts, and packaging — then identify how and where engraving can add value,” Kelly stated.

In addition, evaluate volume production, throughput goals, and the ability to scale output long-term, as volume often dictates space and equipment requirements.

“Flatbed systems require more floor space to accommodate the working area and operator access, while galvo systems are generally more compact and can fit into smaller shop environments or production lines,” he explained.

For example, the Trotec Laser’s galvo features a 12“ X 18“ working area, while their flatbed covers 49“ X 28“.

Regardless of the system setup, Garikiparthi suggested “a decently-sized area” for anything over 100 units per day, giving engravers space to spread out and be creative.

Trusted quality, desired functionality, and overall capabilities also impact the right equipment investment — and budget. Do not skimp where it counts, they agree.

“Be cognizant of the laser tubes when looking for the right product. Unless you are tight on budget or lower production level, you should be looking for a metal tube for your laser,” Garikiparthi noted. “They last considerably longer and are more of a workhorse.”

Industry colleague Wang advises against investing in a CO2 galvo with no cutting head and/or low wattage compared to a user’s desired cutting thickness.

“Don’t buy a machine that requires you to make multiple passes — decreasing quality, tolerance, and accuracy with each pass,” Wang added.

Of course, as the world automates at lightning speed, company representatives also emphasize investing in professional-grade equipment with strong software support to enhance workflow efficiency and ensure more consistent results – further maximizing the return on investment.

“The biggest learning curve is always the software itself — learning proper alignment and how to use parameters, adjust them, and maximize speeds and feeds,” said Wang. “Master your average parameter settings and you will master your craft.”

She also encourages owners to look past the machine itself and consider consumables and spare part availability, as well as U.S.-based technical support, in the decision-making process.

“Be wary of unclear service or warranty terms, limited material compatibility, or systems that appear inexpensive upfront but lack long-term reliability, training, or support,” Kelly added.

In the end, a laser purchase should be viewed as a long-term business tool, rather than a short-term cost. While laser systems are a significant investment, Kelly said demand is soaring and the ROI is strong.

“Financing and tax incentives often make ownership more accessible, and the ability to diversify services and tap into new markets can quickly offset the initial cost,” he said.

Maintaining for the long haul

According to company representatives, routine maintenance is minimal but essential to operate efficiently and extend the equipment’s lifespan.

“Wipe down the interior of the unit, shop vac the excess material in the catch tray, and clean the focal lens with a microfiber cloth,” Wang said.

For those who want a helping hand in maintenance, companies like Trotec offer service plans and annual health checks to keep systems running at peak performance.

While galvo systems typically require less day-to-day maintenance due to fewer moving parts, users should be mindful to monitor laser tubes and small parts such as mirrors for natural wear and tear.

“The lifespan of the functionality is more often tied to the laser tube than the mechanical components of the laser, such as the laser head or controller board. Glass tube lasers typically only have lifespans of 10,000 hours, whereas metal (RF) tubes can last up to 40,000,” Garikiparthi explained.

Regardless of the laser system, proper fume extraction is critical for operator safety, machine performance, and material quality. Filtration systems remove harmful particles and gases generated during laser processing — protecting both people and equipment, while ensuring consistent, high-quality results.

“With proper care and maintenance, lasers can last 10-plus years, with many systems in the field performing well beyond that. Regular maintenance and access to replacement parts and service extend longevity, ensuring a strong return on investment,” Kelly said.

Capitalize on demand

As more independent shops and hobbyists enter the engraving market, you must dare to be different. At first, tap into profitable, high-demand categories with guaranteed interest to hone your craft, then identify a specialization or niche to best serve. Build a lasting rapport with fellow community businesses, teaming up with trophy shops, schools, realtors, and even corporate gift suppliers. Remember to lean into the business’s strengths, bundle services where appropriate, and master the art of customer retention.

With a captured audience and engraving services on a steady incline, the time is right to laser your focus on personalization.